Manufacturing Techniques for Improved OEE

What Is Perfect Production?

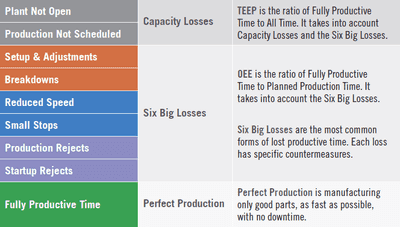

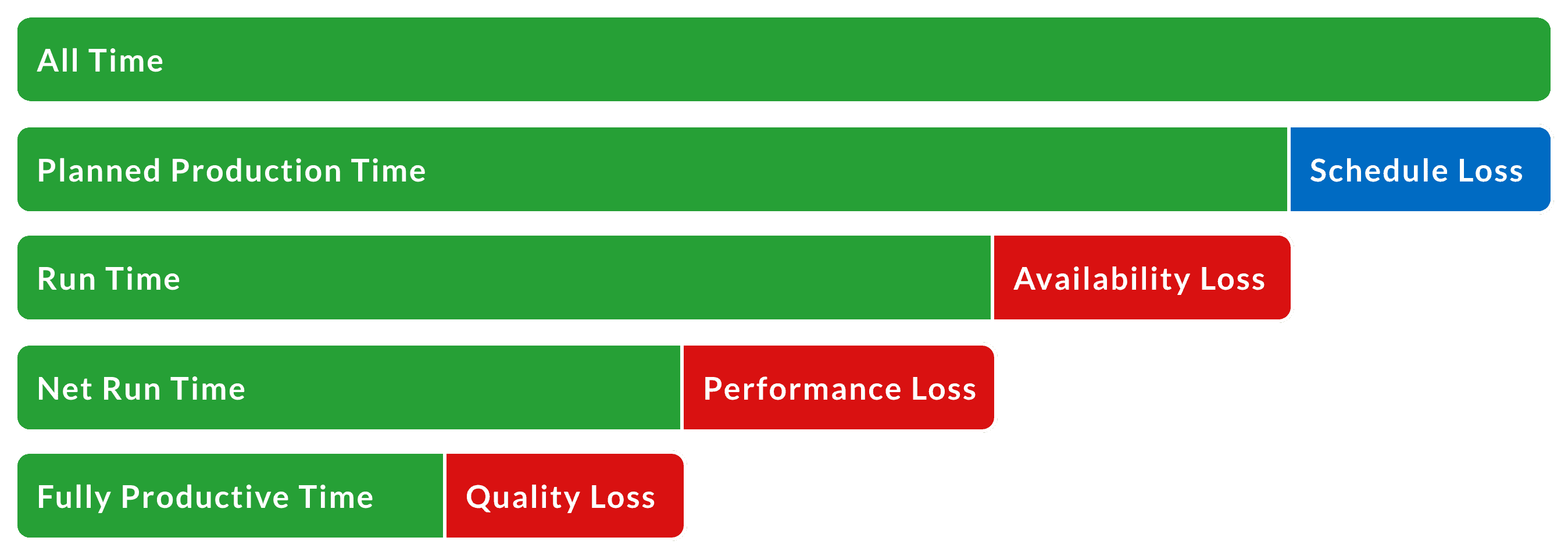

We coined the term Perfect Production from the goal of achieving a perfect OEE (Overall Equipment Effectiveness) score. In other words, Perfect Production is manufacturing only good parts, as fast as possible, with no down time.

Turns out — the pursuit of Perfect Production is a very challenging endeavor (to put it mildly). So we aim to make it easier. Much easier.

Our manufacturing techniques offer a completely modular approach that draws on best practices from the entire world of manufacturing — lean production, theory of constraints, six sigma, and many other sources. It also draws significantly from the world of coaching, leadership, and self-development.

Lean Manufacturing Techniques

Our goal is to make it exceptionally easy for you to improve manufacturing productivity. With that in mind, this page presents best practices for working towards Perfect Production. These best practices share four core characteristics:

Easy

We emphasize approaches that are easy to understand and easy to implement. Even complex techniques can be made more accessible.

Practical

We are realistic about what is within the reach of most teams to accomplish and the resource limitations that we all face (time and money).

Flexible

We don't tie ourselves down to any one process or framework. Instead, we collect and leverage proven techniques regardless of their source.

People-Focused

People like you play a critical role in creating sustainable long-term change. That's why we cover topics like leadership and coaching.

There are four types of techniques ranging from specific manufacturing improvement tools, through to broad leadership strategies:

| Type | Description |

|---|---|

| Methodologies | Best practices for identifying and eliminating waste in manufacturing. These best practices are drawn from a wide range of approaches, including Lean Manufacturing, Six Sigma, and the Theory of Constraints. |

| Metrics and Measures | Data is the foundation for manufacturing improvement. Understanding key manufacturing metrics and when to use them will enable you to benchmark your progress and focus your efforts where they will have the greatest impact. |

| People-Focused | While metrics and measures quanitfy progress, it is people who implement the changes that are being measured. That is why it is important to properly train and continually develop employees of all levels. These topics are a great starting point for job-related growth in manufacturing operations. |

| Tools and Techniques | An array of strategies to keep in your manufacturing improvement arsenal. These tools and techniques are designed to help you achieve quick wins and make fast progress. |

Methodologies

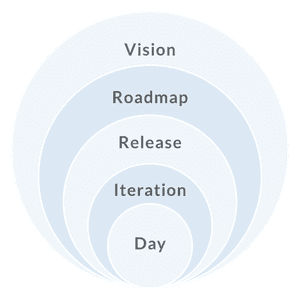

Agile Planning in Manufacturing

Small tasks. Big focus. Get things done.

Deliver small chunks of business value in short release cycles. For each cycle, choose whatever will deliver the most value and get it done. Do away with complicated master plans and be evolutionary and adaptive.

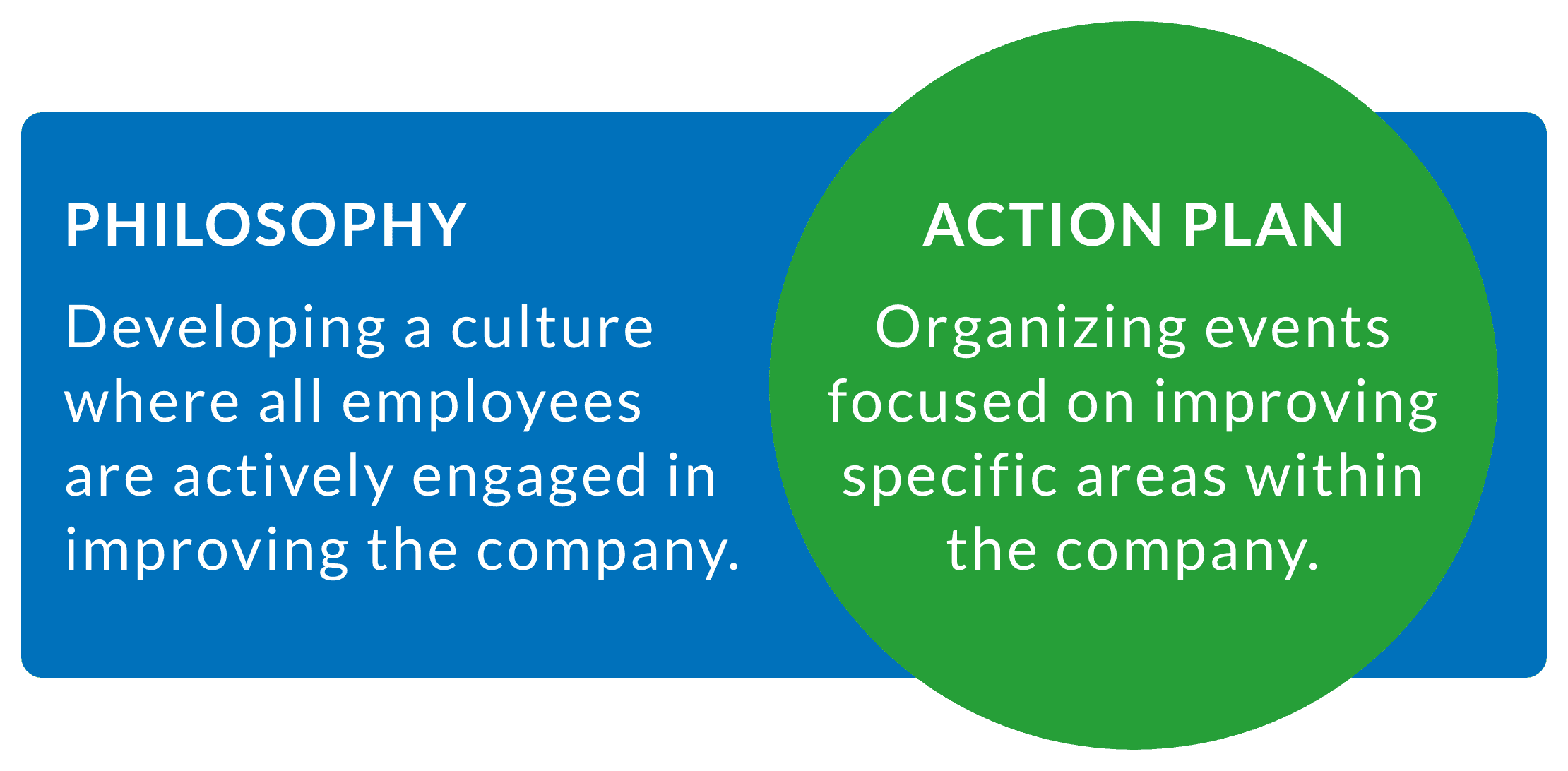

Continuous Improvement

Always improve. Never fall behind.

Creating a culture of continuous improvement in your workplace makes it a core part of your business. This combats the tendency to only make improvements after something in your process goes wrong, and it helps you to be proactive instead of reactive.

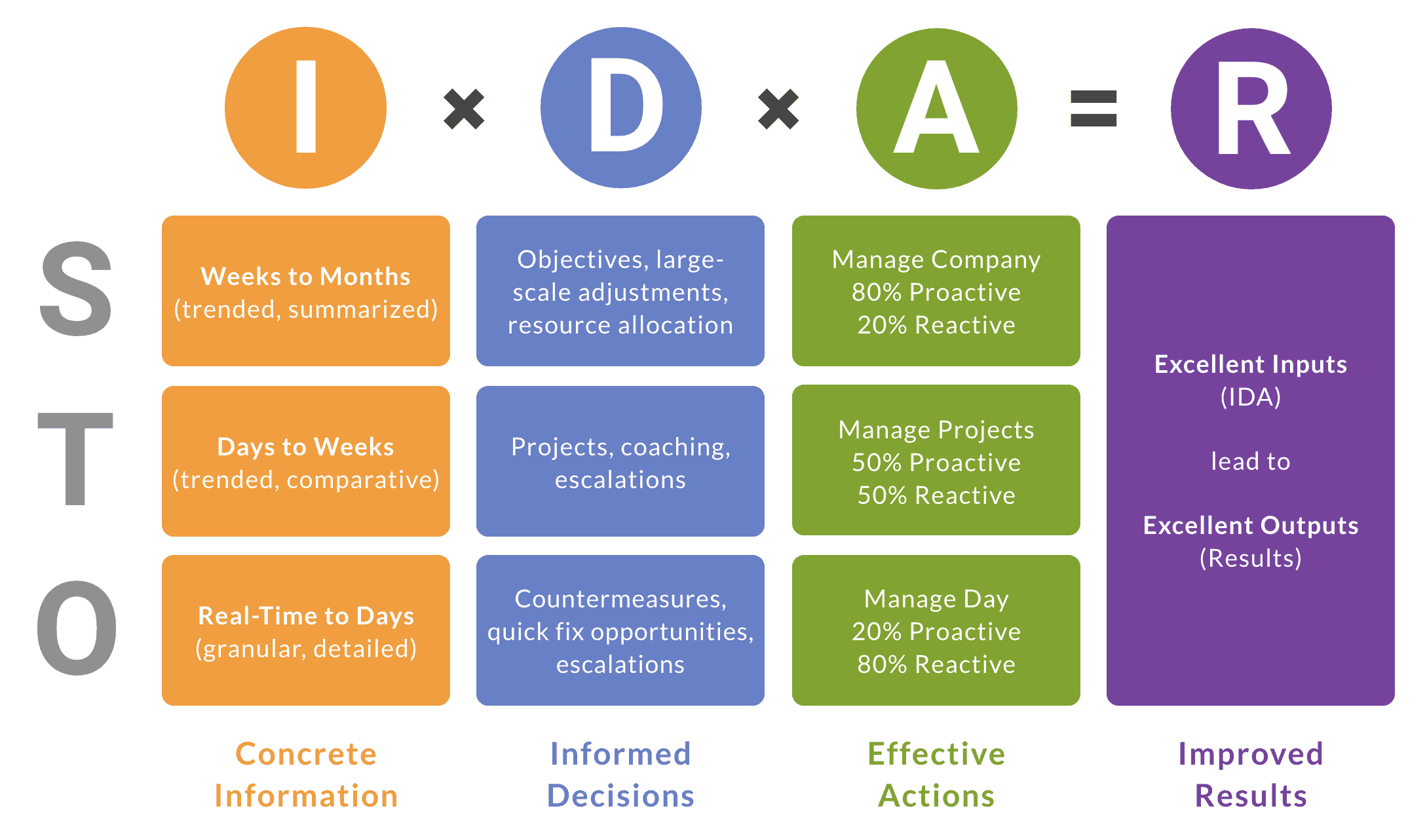

IDA (Information, Decision, Action)

An important way to improve results.

Most companies place too much emphasis on results (looking backward) and too little emphasis on the factors that drive results: Information (the basis for effective decisions), Decision (making effective decisions), and Action (transforming decisions to results).

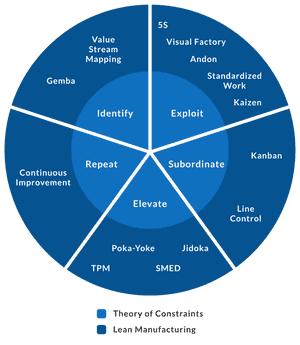

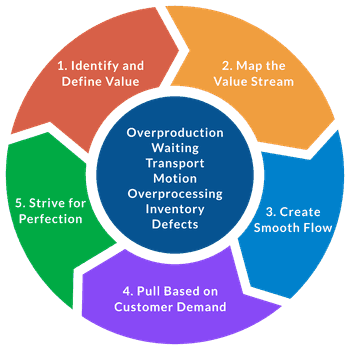

Lean Manufacturing

Cut waste. Add value. Be lean.

Rejected parts, time spent searching for misplaced tools, and buildup of WIP items at the constraint of the manufacturing process are all different forms of waste that create unnecessary costs for manufacturers and consumers alike. Lean manufacturing provides methods to eliminate each of these forms of waste, one step at a time.

Structured Improvement

Strategic. Tactical. Operational.

Deliver superior results by defining an improvement objective, capturing information related to that objective, and using that information in connected meetings (strategic, tactical, and operational) to drive decisions and actions.

Theory of Constraints

Identify. Measure. Improve.

Each manufacturing process has a constraint (bottleneck). Focusing improvement efforts on the production constraint is the fastest path to improved productivity.

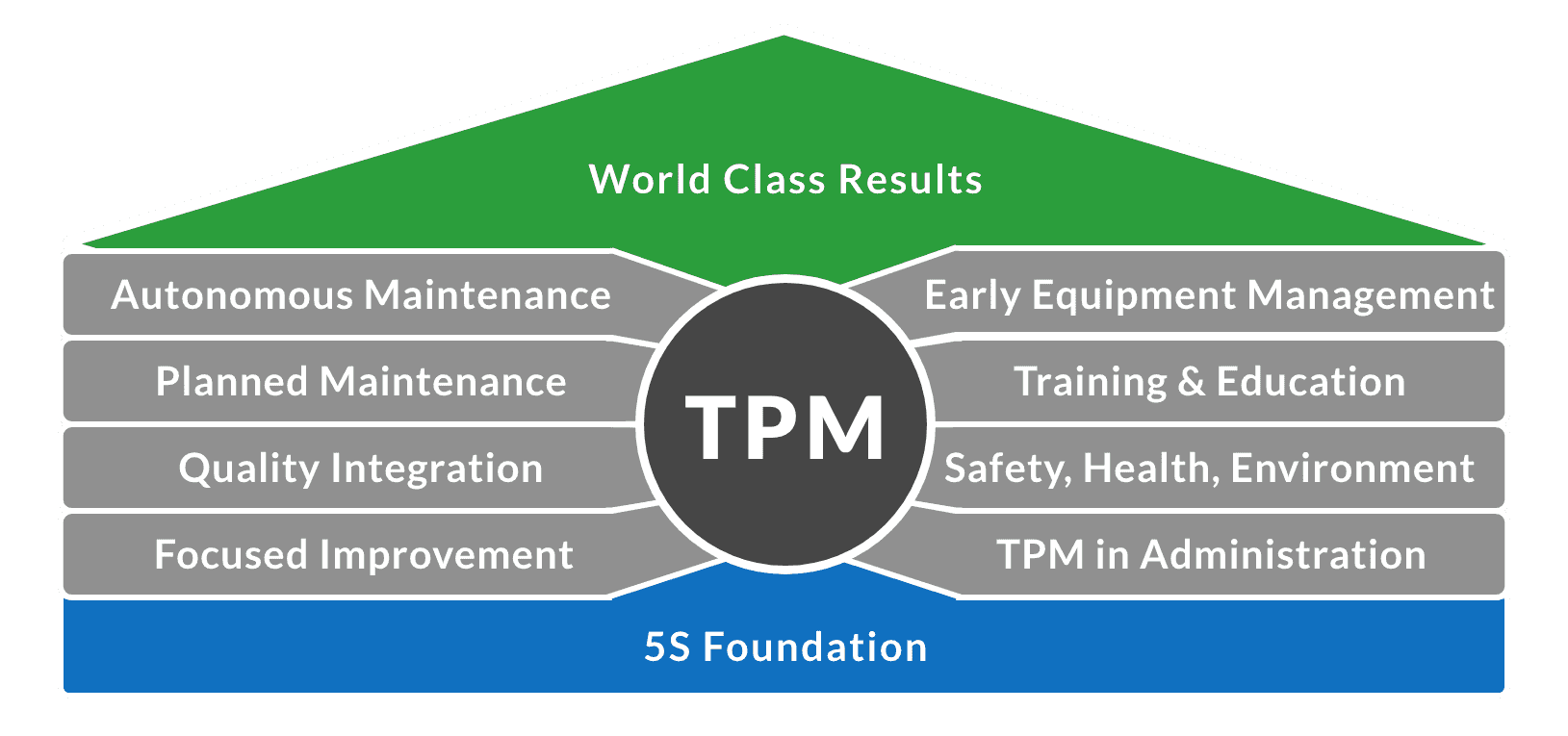

Total Productive Maintenance

Prevent problems - fix them before they even happen.

Total Productive Maintenance benefits manufacturers and end customers alike through an ongoing focus on proactive and preventative maintenance. TPM reduces waste by reducing instances of equipment wear, damage, and failure, which ultimately translates into cost reductions.

Toyota Production System

TPS: Where lean was born.

Many of Lean Manufacturing’s best-known tools, such as Poka Yoke, Kanban, and SMED, came to be as a result of the Toyota Production System. By identifying what your customers are and are not willing to pay for, and eliminating that which they deem waste, you can maximize your company’s value-added activities and profitability.

Metrics and Measures

Downtime

Take control of your (down)time.

Downtime is the largest source of lost production time for most manufacturers. Here are some practical tips for reducing Downtime that don't require a lot of outside support.

Key Performance Indicators

You can't fix what you don't measure.

Consistently monitor a manageable number of KPIs that are aligned to achievable goals to enable your manufacturing operation to accurately measure progress towards critical goals and make well-informed, timely decisions.

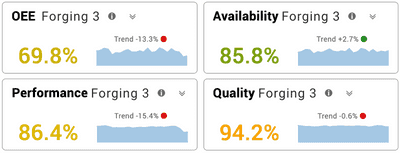

Overall Equipment Effectiveness (OEE)

A yardstick for manufacturing productivity.

OEE measures how close you are to Perfect Production (manufacturing only good parts, as fast as possible, with no down time). It is a great metric for benchmarking progress in improving manufacturing productivity (i.e., eliminating waste).

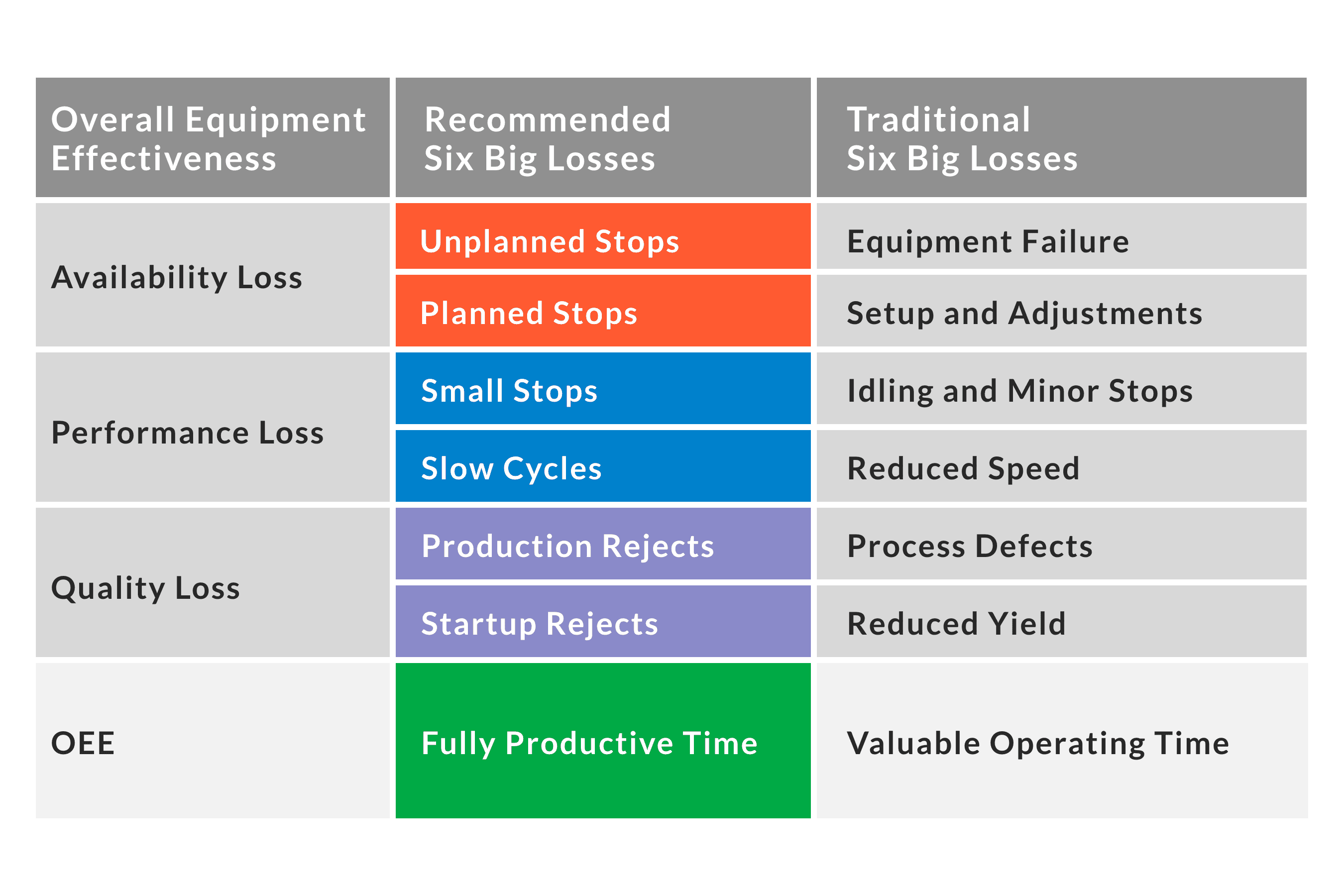

Six Big Losses

An excellent target for improvement actions.

The Six Big Losses are a very effective way to categorize equipment-based losses: Unplanned Stops, Planned Stops, Small Stops, Slow Cycles, Production Defects, and Startup Defects. They are aligned with OEE and provide an excellent target for improvement actions.

People-Focused

Be Your Best

Be Inspired. Do Great Work. Change the World.

Select a small number of truly important things and do those things exceptionally well. Challenge yourself to achieve more, perhaps much more, and show up to work every day as your best self.

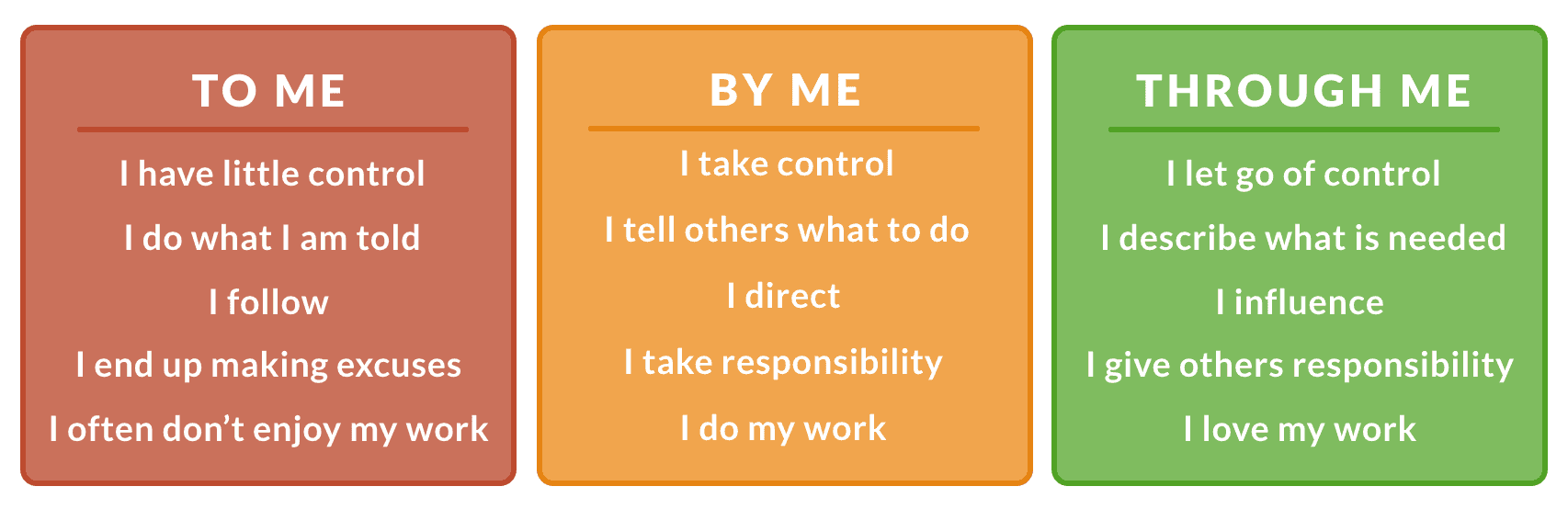

Leadership in Manufacturing Operations

Inspire others and accelerate change.

Inspire others to do their best work and you leverage your most important resource – people. Leadership is a learned skill. Improve your effectiveness as a leader and you improve your ability to create and accelerate change.

How to Run Great Meetings

Decisions. Actions. Change.

Spend less time in meetings while dramatically increasing their value. Great Meetings are organized, focused, fast, positive, participative, and proactive. Participants come prepared and leave energized. Great Meetings result in decisions and action.

Tools and Techniques

Andon

Stop the line now. Save time later.

An Andon is a real-time visual indicator at the production line that is triggered by an operator to bring attention to an emergent problem with the express purpose of immediately addressing that problem with a long-term fix.

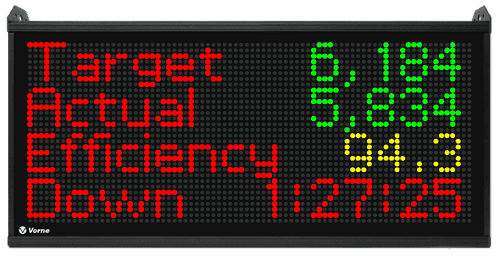

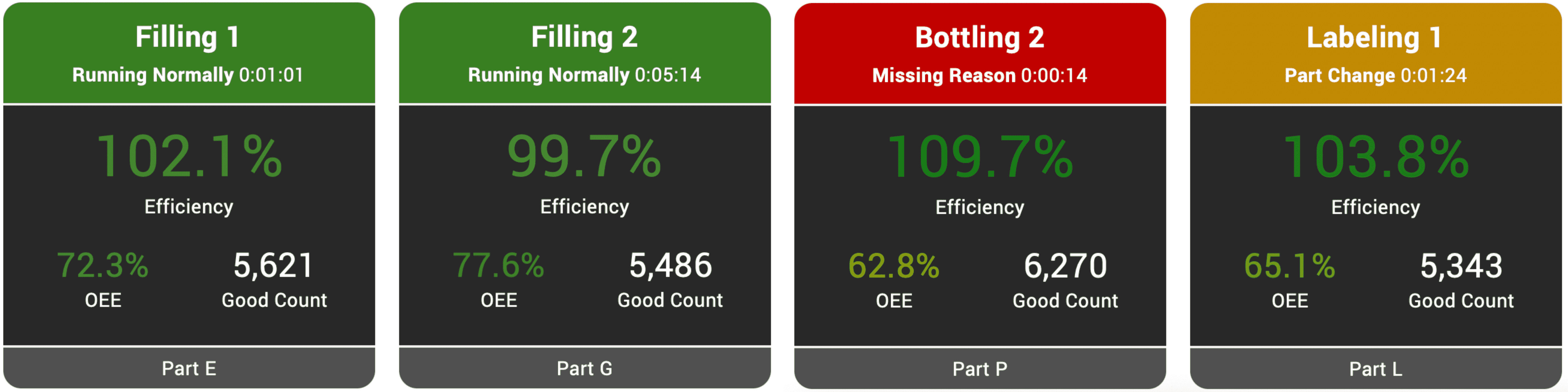

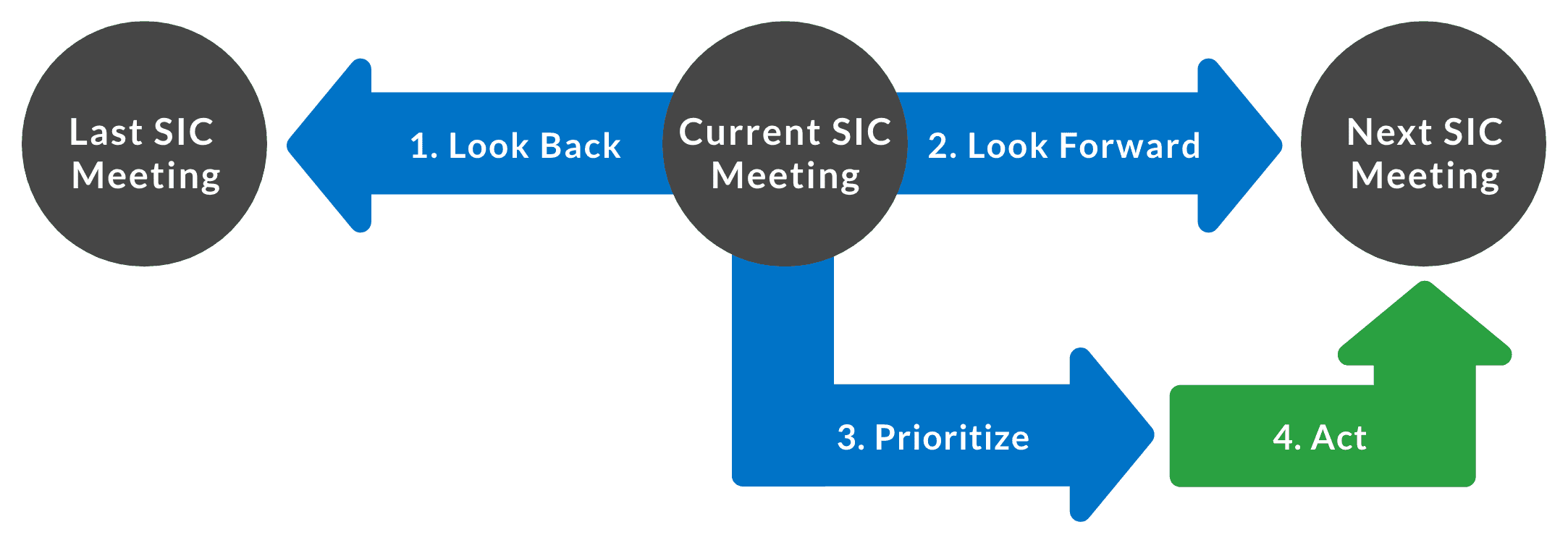

Short Interval Control (SIC)

Small actions add up to large improvements.

Quick and focused reviews of performance data during the shift enable ongoing course corrections and small-scale fixes that collectively result in significant improvements in performance. Look at the immediate past to guide actions for the immediate future.

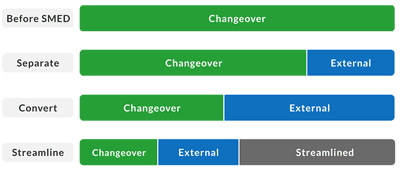

Single-Minute Exchange of Die (SMED)

Reduce changeovers to under 10 minutes.

Changeover times can typically be reduced to less than 10 minutes (i.e., single-digit minutes). Analyze each element of the changeover to see if it can be separated (moved external to the changeover), converted (modified to be external), or streamlined.

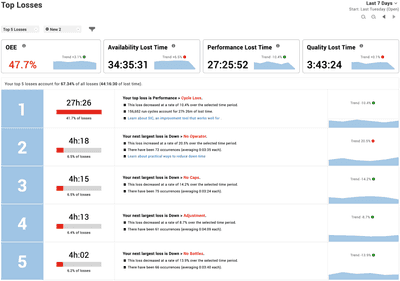

Top Losses and Production Loss Analysis

Attack your top sources of lost production.

Time is precious, so spend that time fixing the most important things — your top sources of lost manufacturing productivity. Track your Top Losses. Pick the biggest actionable loss. Fix it. Repeat.

Visual Factory

See improvement right before your eyes.

It is much faster and easier to take in visual cues as opposed to written or verbal information. That is why the visual factory is vital to lean manufacturing - it allows operators to take in information as efficiently as possible so that they can spend more of their time ensuring production runs smoothly and taking improvement actions.