Overall Equipment Effectiveness (OEE)

OEE Definition

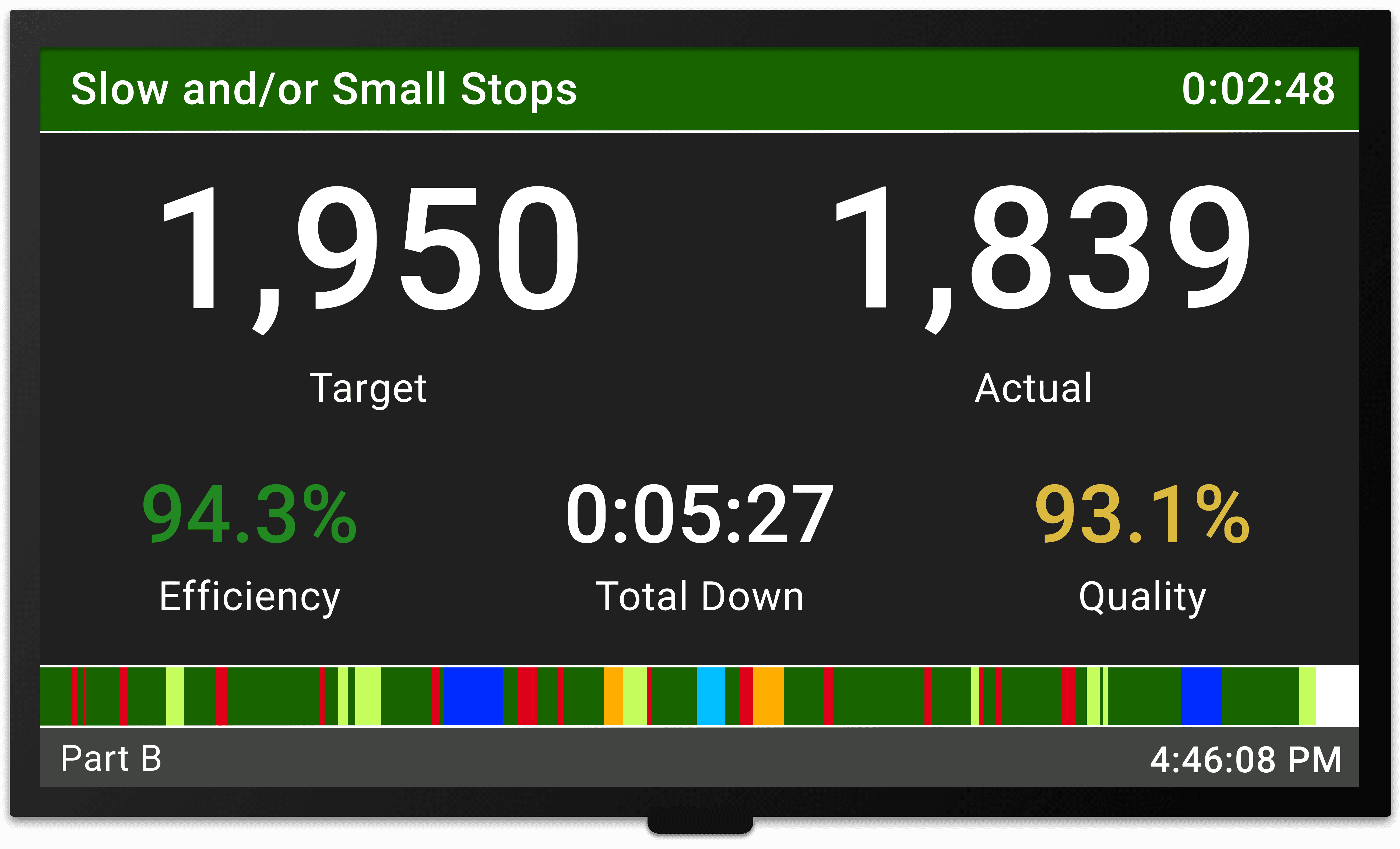

OEE is an abbreviation that in full form represents the manufacturing metric Overall Equipment Effectiveness. OEE takes into account the various sub-components of the manufacturing process – Availability, Performance, and Quality. After the various factors are taken into account the result is expressed as a percentage.

OEE Percentage Formula

This OEE percentage can be viewed as a snapshot of the current production efficiency for a machine, line, or cell.

OEE = Availability x Performance x Quality

Expanded OEE Definition

Manufacturing a product is a complex process. Without metrics and guidelines, it is very easy to lose control and have your business managed by your production.

OEE Data

OEE is a tool that combines multiple manufacturing issues and data points to provide information about the process. By analyzing and calculating data it also functions as a framework for root cause analysis. Through a documented process of combining the underlying data, OEE provides specific process information. All members of the manufacturing team, from assembly technicians to financial personnel, can use the data to understand the current state of the manufacturing process.

The 4 Components of the OEE Framework

By having a predetermined framework of the impact of machine availability, performance, and quality, OEE provides a framework to track underlying issues and root causes. OEE also provides a framework for improvements in the manufacturing process. By using key OEE concepts such as The Six Big Losses waste exposed by tracking OEE can be understood and efficiencies can be improved.

The 4 components of this framework are:

- OEE

- Availability

- Performance

- Quality

OEE is a very simple metric to immediately indicate the current status of a manufacturing process and also a complex tool allowing you to understand the effect of the various issues in the manufacturing process and how they affect the entire process.

Basic OEE Formula

The basic OEE formula is availability times performance times quality, which in equation form is:

Availability refers to the machine or cell being available for production when scheduled. At the most basic level, when a process is running it is creating value for the end-user. When a process is stopped, it's creating a cost with no associated value. Whether it's due to mechanical failure, raw materials, or operator issues, the cell or machine is either producing or not producing. By comparing scheduled run time to actual run time, the availability component of OEE allows for a determination of lost production due to downtime.

Performance is determined by how much waste is created through running at less than optimal speed. By comparing the actual cycle times against ideal cycle times, OEE allows for a determination of how much production was lost by cycles that did not meet the ideal cycle time.

Quality focuses on identifying the time that was wasted by producing a product that does not meet quality standards. By comparing the quantity of good to reject parts the percent of time actually adding value by producing good product is exposed.

Top 5 Benefits of Using OEE in Manufacturing

By itself, OEE only provides data about your manufacturing process. Companies that use OEE as a metric have found success when combining it with general lean manufacturing programs and also as part of TPM systems. When using OEE with these systems the benefits become significant:

- Directly tie production efficiencies to fiscal reporting

- Reduce investigation time for root cause analysis

- Shorten equipment ROI through increased utilization

- Decrease costs through waste elimination

- Increase customer satisfaction through quality improvement

OEE allows companies to pull separate business functions together with a single useful metric.