Takt Time

Takt Time in Manufacturing

Matching your production levels to customer demand reduces waste by preventing the buildup of excess inventory while safeguarding against unplanned increases in production to meet demand. This creates a steadier, more efficient manufacturing process.

Why Calculate Takt Time?

Takt time paces production in a way that aligns it with customer demand. It is an important concept in lean manufacturing because it balances the importance of meeting customer demand with the importance of minimizing work-in-process and inventory. Think of takt time as establishing the “rhythm” or “beat” of your manufacturing process. In fact, takt is a German word that means cadence, rhythm, time, measure, bar, or cycle.

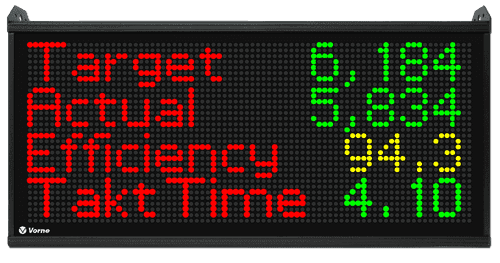

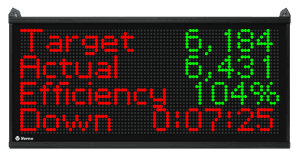

In practical terms, not only does takt time establish the pace of production, it provides an easy way to see if you are ahead of schedule, behind schedule, or right on schedule. How? By using takt time to drive a real-time target for schedule adherence. A very popular plant floor scoreboard display is target (how much should have been produced thus far) versus actual (good parts actually produced), along with efficiency (the ratio of actual to target).

In practice, takt time is often used to match the pace of production to “normalized” customer demand (customer demand or estimated demand averaged over a longer period of time). Takt time is also an integral part of standardized work, as the whole idea is to establish a predictable and repeatable pace of production (i.e., standardized production).

Takt Time Formula

The formal calculation of takt time is:

Takt Time = Production Time / Customer Demand

Let's take this takt time formula apart.

Production Time

Production Time is the available time for manufacturing parts. It should only include time when production is expected to be running. From the perspective of production states (Run, Unplanned Stop, Planned Stop, and Not Scheduled), Production Time only includes the first two (Run and Unplanned Stop). In other words, Production Time does not include any time where the line is expected to be stopped (e.g., it does not include lunches, breaks, changeovers, or planned maintenance).

Customer Demand

Customer Demand is the quantity of parts to manufacture over some specified period of time to keep pace with customer orders. In practice, many companies choose to base customer demand on their expected rate of production (the customer in this case being more of an internal entity).

Takt Time

Takt Time is the amount of time needed to manufacture one good part, while keeping pace with customer demand (e.g., manufacturing one good part every 12.7 seconds). Delving deeper, it represents a “normalized” time. Sadly, manufacturing processes do not have a magic dial that can be arbitrarily changed every day based on customer demand. So, takt time represents what the production process needs to achieve in order to meet customer demand over some “normalized” period of time.

Takt Time Calculation Example

Now that we have established some of the key concepts, let's work a calculation example.

The first step is to calculate production time for a period of time (typically one shift). If the shift is 8 hours, with one 10-minute break and one 20-minute lunch, and there are no other planned stops whatsoever, the production time will be 450 minutes (8 hours x 60 minutes per hour – 10-minute break – 20-minute lunch).

The next step is to calculate customer demand. Our recommended approach is to pick a longer time horizon, such as one week or one month, and then translate that down to one shift. For example, if the requirement is to manufacture 17,500 parts this week, and the week consists of one shift per weekday (5 shifts), the customer demand is 3,500 parts per shift (17,500 parts per week / 5 shifts).

The last step is to calculate the takt time for the shift, which in this case is 0.1286 minutes (450 minutes of production time / 3,500 parts per shift of customer demand) or 7.72 seconds (0.1286 minutes x 60 seconds per minute).

How to Use Takt Time

Here are three ways to leverage takt time in your manufacturing operation:

- Improve Production Planning

- Pace Production to Schedules

- Use Efficiency to Win the Shift

1. Improve Production Planning

Customer demand is rarely steady. Manufacturing performance is also rarely steady. They both tend to fluctuate. When scheduling production, use historical manufacturing information to validate whether the calculated takt time is attainable. Using historical information when creating the production plan gives you an opportunity to amend your production standards to ensure that the plan is met without missed shipment dates (unhappy customer) or overproduction of parts (unhappy plant manager). Make everyone happy with takt time!

2. Pace Production to Schedules

Use takt time to drive a plant floor scoreboard that paces production in real-time. Each time the takt time elapses the target counter should increment. Converting takt time into a real-time target makes it easy to instantly identify if your production is ahead or behind schedule. If production of good parts falls behind the real-time target, devote additional resources to getting production back on track. If production is considerably ahead of the target, consider investing time towards a 5S, cleaning, or maintenance activity.

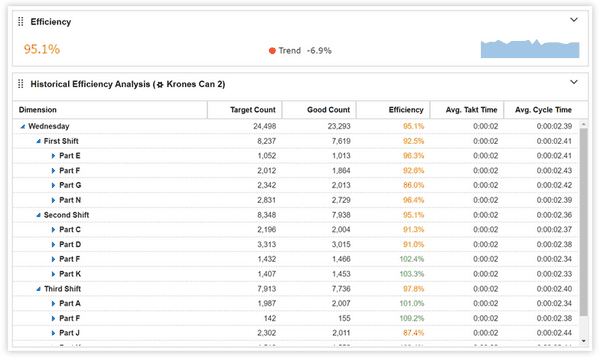

3. Use Efficiency to Win the Shift

Sometimes a conscious decision is made to run production slower than its “ideal” speed (slower than the ideal cycle time). This can have a negative effect on your Overall Equipment Effectiveness (OEE) score. Instead of focusing your plant floor team on OEE, focus your plant floor team on efficiency (the ratio of good pieces to target count) and give them the tools to consistently win their shift (achieving 100% efficiency).

Use takt time to align your rate of production to customer demand. It is an excellent tool for hitting the sweet spot of meeting customer demand without overproducing (without creating excess work-in-process and inventory). Specifically, use takt time to drive real-time manufacturing targets for your plant floor team.

Takt Time Tool Comparison Chart

The following selection chart highlights some of the many advantages of using the Vorne XL Productivity Appliance™ for Takt Time applications. We like to think of XL as the ultimate takt time tool!

| Advantage | Takt Board | Takt Timer | Vorne XL Productivity Appliance™ |

|---|---|---|---|

|  |  | |

| Affordable | ✔ | ✔ | ✔ |

| Highly Visible | ✔ | ✔ | |

| Engages Operators | ✔ | ✔ | ✔ |

| Automates Data Capture | ✔ | ✔ | |

| Real-Time Information | ✔ | ✔ | |

| Historical Analytics | ✔ | ||

| Browser-Based Reports | ✔ | ||

| Multiple KPIs | ✔ | ✔ | |

| Takt Count Down | ✔ | ✔ | |

| Converts Takt to Target | ✔ | ||

| Takt Overage | ✔ | ||

| Takt Compliance | ✔ | ||

| Takt Efficiency | ✔ | ||

| Count Metrics | ✔ | ✔ | |

| Rate Metrics | ✔ | ||

| Cycle Metrics | ✔ | ||

| Production Time Metrics | ✔ | ||

| OEE Metrics | ✔ | ||

| Six Big Loss Metrics | ✔ | ||

| TEEP/Capacity Metrics | ✔ | ||

| Target Metrics | ✔ | ✔ |