Lean Manufacturing

What Is Lean Manufacturing?

Lean manufacturing is a comprehensive term that refers to a collection of manufacturing methodologies based on maximizing value and minimizing waste in the manufacturing process. Lean manufacturing, sometimes referred to as lean production, has evolved in North America from its beginnings in the Toyota Production System (TPS) in Japan. Many of the most recognizable phrases, including kaizen, andon, and kanban, are Japanese terms that have become standard terms in lean manufacturing.

At the heart of lean is identifying value. Value is defined as any item or feature for which a customer is willing to pay. All other aspects of the manufacturing process are deemed waste. Lean is used as a tool to focus resources and energies on producing value-added features while identifying and eliminating non value-added activities (i.e., waste).

Lean Manufacturing Process

Lean looks at manufacturing, first and foremost, from a customer perspective. By identifying how the customer defines value, lean manufacturing tightly aligns the manufacturing process to the customer. By manufacturing to customer demand, driving out waste, and continuously improving, companies can satisfy customers, employees, and shareholders alike. The goal of a lean organization is to be able to deliver the exact product in the exact quantity with the exact quality that the customer needs exactly when they need it.

Lean Manufacturing and Waste

One of the fundamentals of lean manufacturing is truly understanding the concept of waste. In any manufacturing environment, everyone works to minimize waste. However, lean redefines waste. Traditionally waste has been viewed as an object. It is very easy to envision a barrel of scrap and identify it as waste. In lean manufacturing the term waste actually refers not to the physical material, but rather the relationship of the resource to the end customer. In short, if the end customer wouldn’t want to pay you for it, it is waste.

Beyond concrete waste, such as a rejected part, there is abstract waste, like unnecessary time spent moving around the factory by plant floor employees due to poor organization of tools. Obviously customers don’t want to pay for poor quality goods, but they do not want to pay for wasted time either, since wasted time represents cost that ultimately gets passed to the customer.

Lean Manufacturing and Continuous Improvement

One of the hallmarks of companies that are truly lean is their focus on continuous improvement. Although project-based changes are still more typical at manufacturing companies, a lean environment lends itself to constant change - which can be seen as an agile methodology. An agile approach to lean manufacturing starts with a small amount of planning to create a vision and roadmap, but then quickly moves on to iterative and adaptive releases and iterations, with daily alignments to keep progress on track. This leads very naturally to continuous improvement of manufacturing processes.

By being able to quickly identify and remove waste from the value stream, immediate gains are achieved. A proactive approach towards improvement prevents the losses from occurring in the first instance, in comparison to a reactive approach, in which something must go wrong before action is taken. In a lean environment, there are ongoing safeguards and actions to prevent something from going wrong in the first place. For example, TPM (Total Productive Maintenance) integrates the philosophy of proactive maintenance as a way of reducing unplanned stops and downtime.

Benefits of Lean Manufacturing

Lean manufacturing techniques are used to increase profitability by reducing costs. By understanding how customers define value, costs that do not add value are reduced or eliminated.

Traditional Profitability Formula

Traditional View: Cost + Profit = Sales Price

In the above example the cost to bring your product to market plus profit dictates the selling price of a product. Particularly in our global economy this model is rarely reflective of current practices. Competition and customer demand will often set selling prices. By controlling your costs through eliminating non value-added activities, a well-implemented lean manufacturing environment will directly improve your bottom line.

Lean Profitability Formula

Lean View: Profit = Sales Price – Cost

Lean Manufacturing Cost Savings

When you implement and follow a lean path you should see direct cost savings by driving out waste. You will also see significant improvements in other areas:

- Increased employee morale and productivity

- Higher customer satisfaction

- Faster delivery

Lean manufacturing is customer focused. Since the success of your business as a whole is due in large part to satisfying customer demands, lean allows your manufacturing activities to become more closely aligned with your company goals and activities.

1. Increased Employee Morale and Productivity

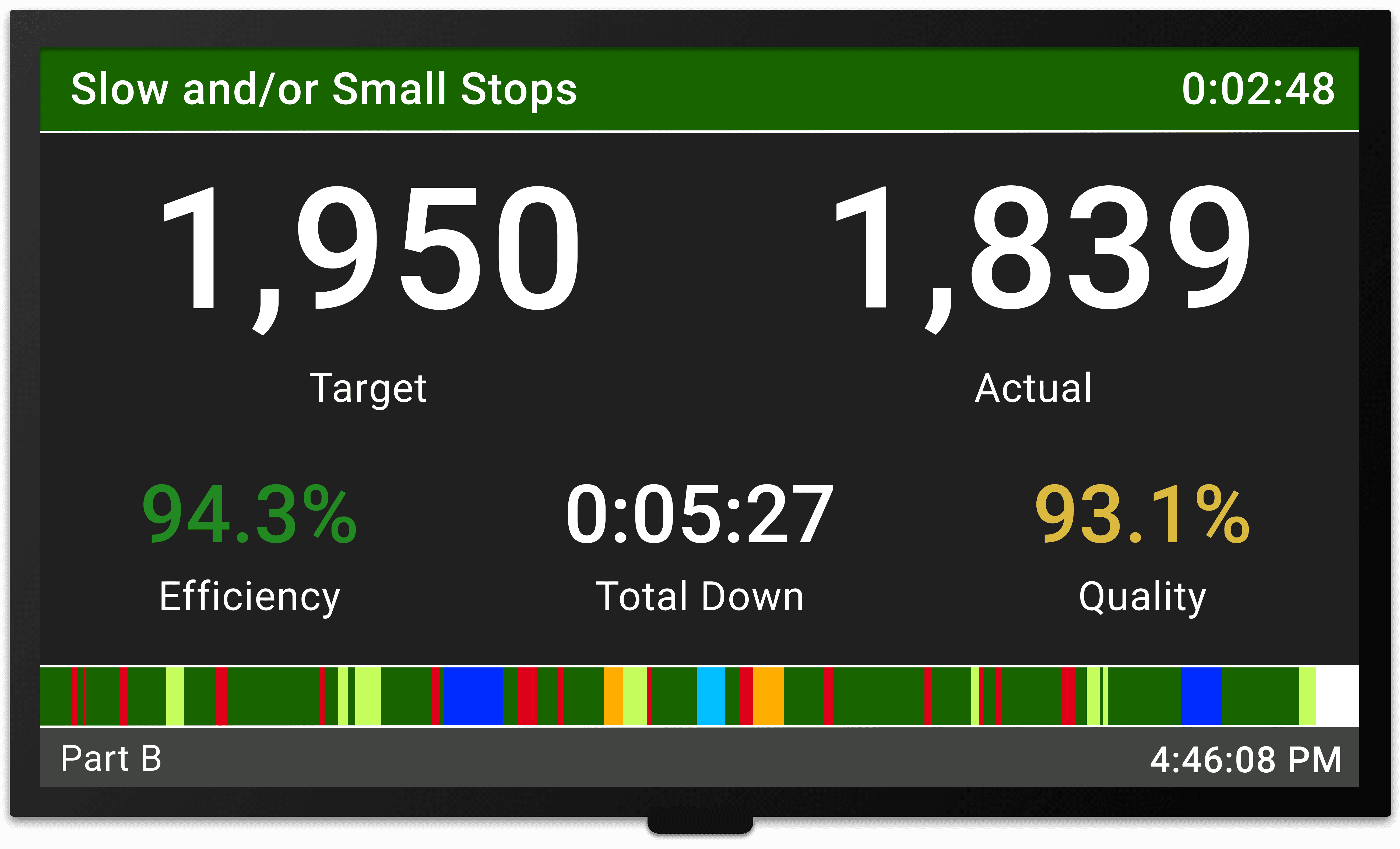

The lean manufacturing process provides clear goals and expectations. When done well, this creates a highly motivating environment for employees. Working toward shift targets with tools to help you meet those targets, such as a carefully established Takt Time, is just one example of how lean can boost morale and productivity. Nothing is more frustrating than working with no benchmark for whether or not you are doing a good job. Seeing goals, progress, and even the potential to exceed expectations promotes a happy, productive workforce.

2. Higher Customer Satisfaction

Customers pay for your products, so they can also be your biggest critic. They expect flawless goods delivered almost instantly for a very low price. While this is not realistic 100% of the time, the closer you can get to delivering quality goods as fast as possible and on the customer’s schedule, the more successful your organization will be. The close alignment in lean between you and your customer makes it much more likely that you will meet their expectations.

3. Faster Delivery

Improving efficiencies across your manufacturing system will naturally translate to faster and more adaptive delivery. By reducing waste, a lean factory is better able to quickly adjust to supply chain disruptions, changes in customer demand, and other unforeseen circumstances. Less buildup of inventory means that if demand changes, no product has to be thrown away and production of the new product or product variant can quickly begin. A sudden increase in demand can be met with an immediate increase of production, with disruptions much less likely as machines are kept in good condition and targets are clearly tracked and displayed. By following a lean methodology, you create a direct, uninterrupted path for production from start to finish.