Today’s food and beverage producers are under pressure to:

- 1. Continually increase margins and profitability through process improvement, and

- 2. Maintain the quality their customers have come to expect.

It is difficult to deliver improvement projects while maintaining quality and brand standards. Therefore, it is critical to implement production monitoring solutions that do not disrupt your manufacturing processes or affect the finished product. Vorne XL is exactly such a solution: No software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates.

Driving Improvement for Food and Beverage

Our food and beverage users make something tastier, healthier, or more innovative than other options on the market, so it is critical to be able to optimize the process while maintaining the product that customers love.

The Vorne XL Productivity Appliance empowers food and beverage manufacturers to monitor their processes, improve throughput, and maximize efficiency, all while preserving the integrity of their products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line.

Key Benefits for Food and Beverage

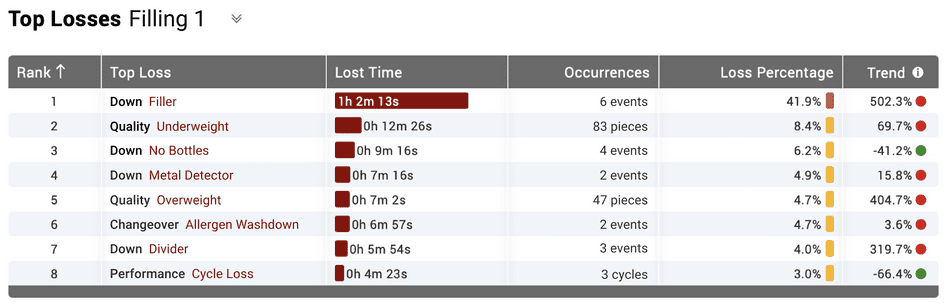

Vorne XL products are completely non-specialized with regard to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any line and get the same wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. It scales from machine to enterprise. Monitor filling machines, cappers, labelers, checkweighers, case packers, and other equipment with the one solution, quickly seeing benefits such as:

- 1Optimized Changeover Efficiency Understand the true impact bottle changes or label changes have on production time and set targets for completing CIP, sanitization, or allergen wash events.

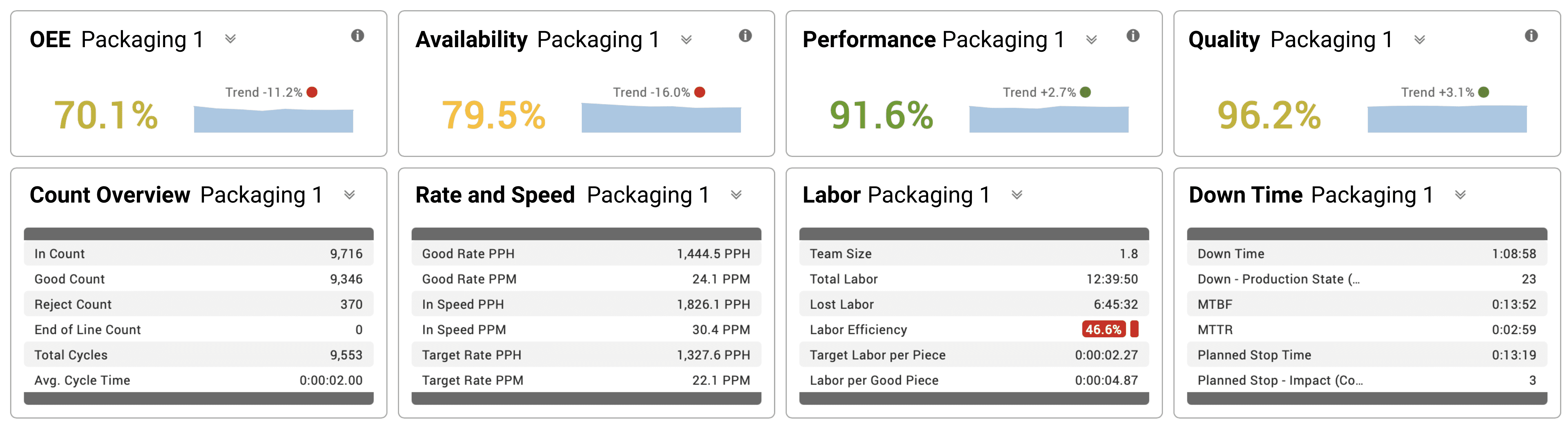

- 2Comprehensive Job and SKU Tracking Analyze the performance of every job and SKU on your line. For example, precisely know OEE, run rate, cases produced, labor efficiency, etc.

- 3Speed Monitoring and Alerts Isolate periods of time the filler or labeler was running at reduced speed with performance loss metrics, and receive alerts when the line is running slow or down.

- 4Real-Time Performance Visualize the current line speed in PPM or PPH and compare average cycle times against your ICT. Motivate operators to “win the shift” with real-time target counts.

- 5Enhanced Quality Control Gather critical quality loss data by designating multiple reject stations at, for example, a kick-off valve, checkweigher, metal detector, or AOI camera.

You're in excellent company

Vorne XL users span across 45+ countries and are in virtually every industry - including many in food and beverage. Take a look at a sampling of food and beverage manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn more about vorne xl

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 91.9% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL delivers an incredible data foundation and the tools you need to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers who share their success stories.

Food and beverage specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of food and beverage industry specialties. Here are some of the more common specialty areas where XL is used:

- Bakery Products Manufacturing

- Beverage Manufacturing

- Cereal and Grain Processing

- Confectionary Manufacturing

- Dairy Processing

- Food Ingredients Manufacturing

- Food Processing

- Frozen Food Manufacturing

- Meat Processing

- Prepared Foods Manufacturing

- Sauce and Condiment Manufacturing

- Seafood Product Manufacturing

- Snack Food Production

- Specialty Foods Products Manufacturing