Applications

Improve With XL

The XL Productivity Appliance™ is an extremely flexible and powerful tool for improving manufacturing productivity. Our goal with XL is simple – make it incredibly easy for you to achieve unprecedented improvements in manufacturing productivity.

To give you a better sense of how XL can help, we have put together a collection of popular manufacturing applications that are enhanced by XL.

Applications

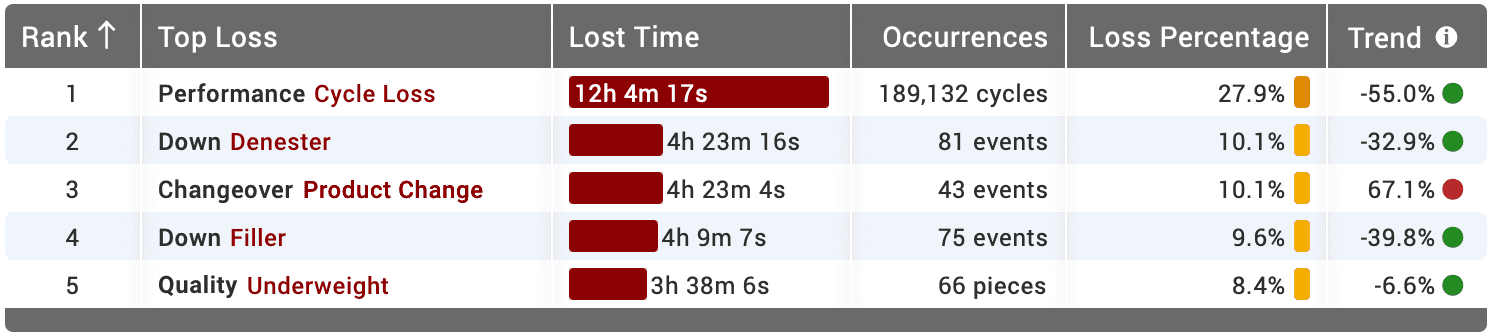

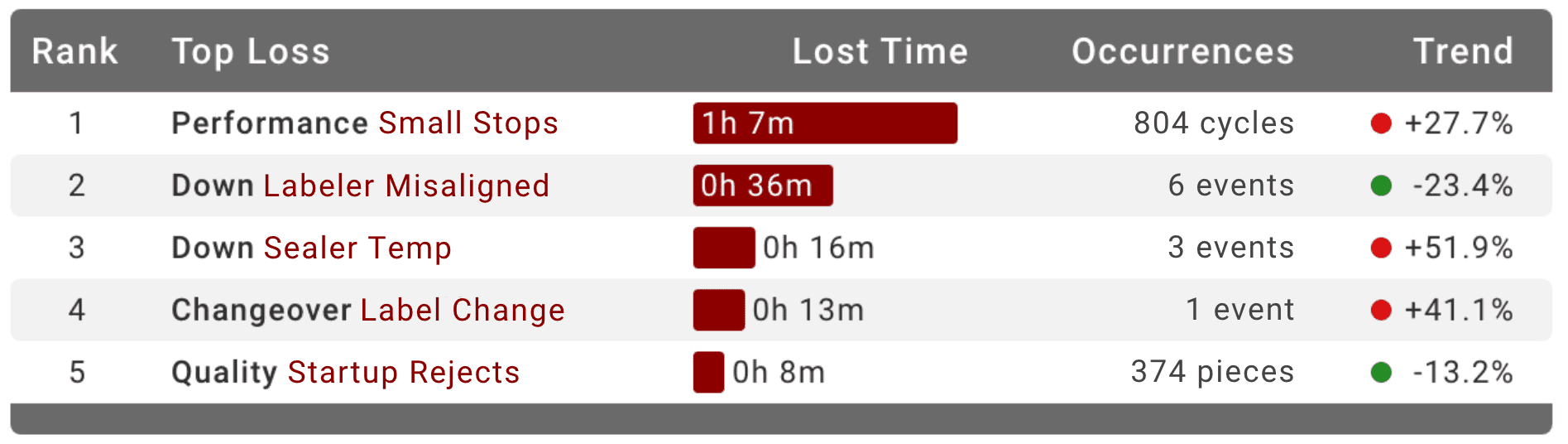

Machine Monitoring

Data-Driven Improvement at Every Level

Machine monitoring uses sensor data and software to provide you with real-time visibility into your manufacturing operations. It enables you to view and analyze production data, transforming real-time data into historical data and analytics.

By implementing automated data collection for key steps in your manufacturing process, you can create a solid data foundation that can be used to drive improvement at every level: from plant floor operator, to line supervisor, to plant manager.

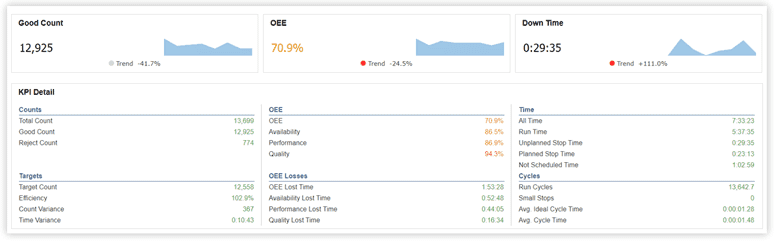

Production Counters

Supersize Your Counts

Use production counters for much more than just counting – use them to drive improved productivity. Did you know that with just two sensors you can generate literally dozens of meaningful and insightful metrics that will help you improve manufacturing productivity? Metrics like Down Time, Run Time, Cycle Time, First Pass Yield, Efficiency, OEE, TEEP, and so, so many more.

Production Monitoring

Ultimate Continuous Improvement Tool

Production monitoring starts with real-time data collection (to create an accurate data foundation) and transforms that data into actionable information (to create a framework for effectively improving your manufacturing process). By reviewing that information within a structured framework that facilitates decisions and actions, you will be able to continuously improve your manufacturing operations. By sharing that information across your organization you will align decisions and actions to your company objectives.

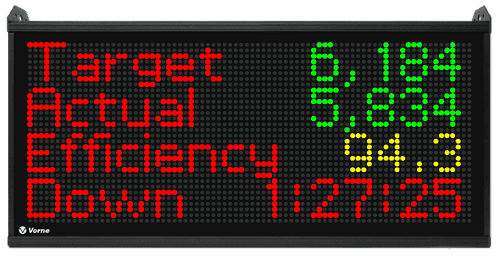

Scoreboards

Win the Shift

KPIs (Key Performance Indicators) are a proven tool for aligning the actions of individuals. They focus a disparate group of people into a high-performance team. When KPIs are used in manufacturing there is an extra dimension to consider – the importance of communicating real-time KPIs to plant floor employees.

Scoreboards are an ideal way to communicate real-time KPIs to your plant floor team. We recommend that you design real-time scoreboards to communicate three types of information: Expectations (“Where should we be?”), Performance (“Where are we?”), and Achievement (“How are we doing?”).

Takt Time

The Rhythm of Production

One of the core Lean Manufacturing principles is to use Takt Time to match the pace of production to customer demand. In practice, many companies choose to use Takt Time in a slightly different way – to pace actual production to the expected rate of production (the customer in this case being an “internal” entity).

Paying attention to Takt Time will help you develop a steady rhythm in production and make it much easier to know if you are ahead, behind, or right on schedule.