Real-Time Production Monitoring System

XL is the simplest and fastest way to monitor and improve production

XL is a standalone device that includes I/O to communicate with your process, a scoreboard for your operators, and built-in reporting for your managers. XL seamlessly scales from machine to enterprise.

XL works on any discrete manufacturing process. That’s one of the reasons it’s used on 42,000+ installations in 45+ countries. Additional benefits of XL real-time production monitoring include:

- No software to install

- No servers to maintain

- No recurring fees

- No contracts

- Unlimited users

- Free 90-day trial

- Free technical support

- Free software updates

M.C. | Industrial Automation Engineer | Global Confectionary Manufacturer

Is XL Production Monitoring right for you?

Here is a quick test of whether XL is right for you.

- Are you tracking production with spreadsheets?

- Do you lack accurate or actionable data?

- Do you have a system, but it’s too hard to use?

XL eliminates manual data capture. Spend your time interpreting data, not tracking it.

XL measures with millisecond precision, removing human bias. Fair warning, you may be shocked to discover your true downtime and the amount of time lost to slow cycles and small stops.

XL creates a “data democracy,” where information and reporting is accessible to everyone. We are amazed by how many XL customers have MES or SCADA systems, but cannot get the information they need.

C.T. | Lean Improvement Team | Global Imaging Products Manufacturer

As Easy as 1, 2, 3

XL provides built-in and customizable real-time production reports for unlimited users, out of the box. It is a hardware appliance that easily scales up from one machine, to one plant, to your entire enterprise. Buy exactly what you need, exactly when you need it.

Sensor

Wire one or two sensor inputs from an existing machine photo-eye, relay, proximity switch, or encoder to XL.

Scanner

Plug a barcode scanner into XL to make it easy for operators to start part runs and scan down time reasons. Print barcodes right from XL.

Network

Connect XL to your network and provide an IP address. No software installation required, access everything through your browser.

The most important feature of XL is easy. We call it XL Easy.

- Easy to Buy: There is zero risk since we recommend that ALL new users start with a free 90-day trial.

- Easy to Install: You can be literally up and running in hours (as shown above).

- Easy to Use: Dozens of built-in reports enable you to analyze data immediately. Drag-and-drop widgets enable you to develop your visuals exactly how you want them.

D.G. | Plant Manager | Hospitality and Healthcare Products and Services

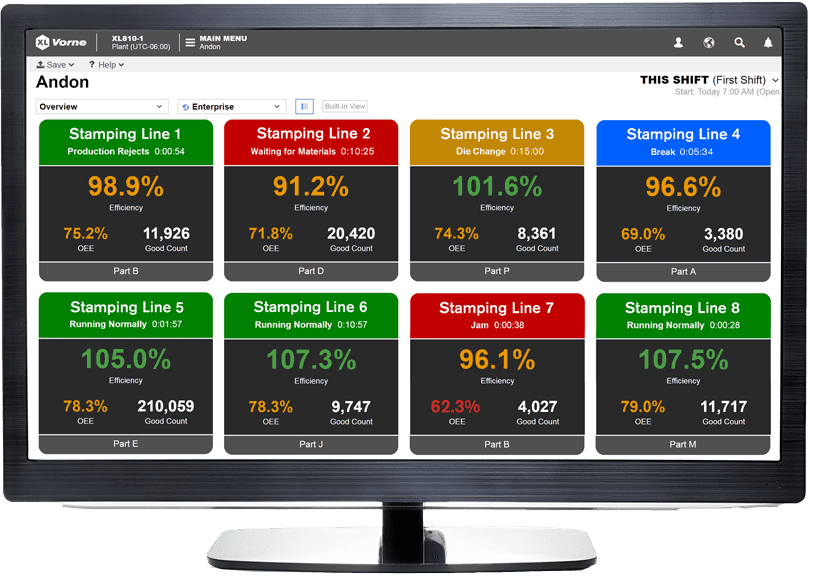

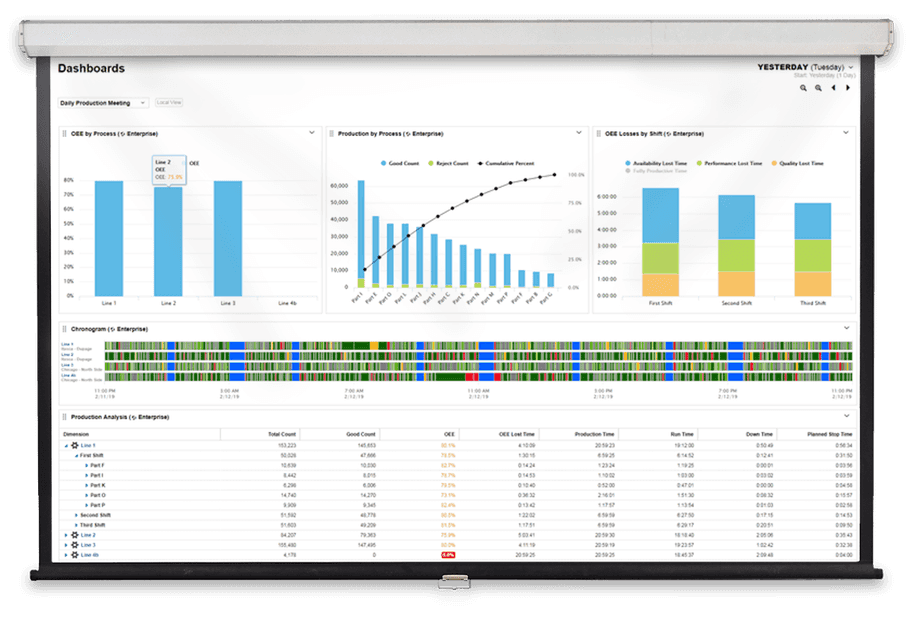

Any report. Any machine. Any time. In real time.

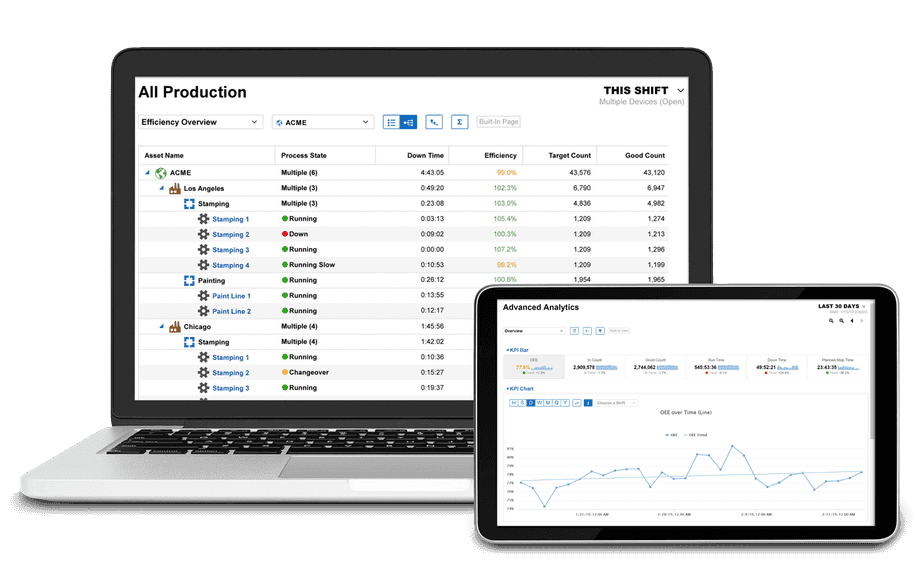

Our patented reporting technology creates a level playing field across your enterprise. With XL on every process, instantly generate reports for a process, area, plant, division, or your entire enterprise. Every XL includes a powerful embedded webserver so there’s no software to install, and your data is instantly available to every user on your network.

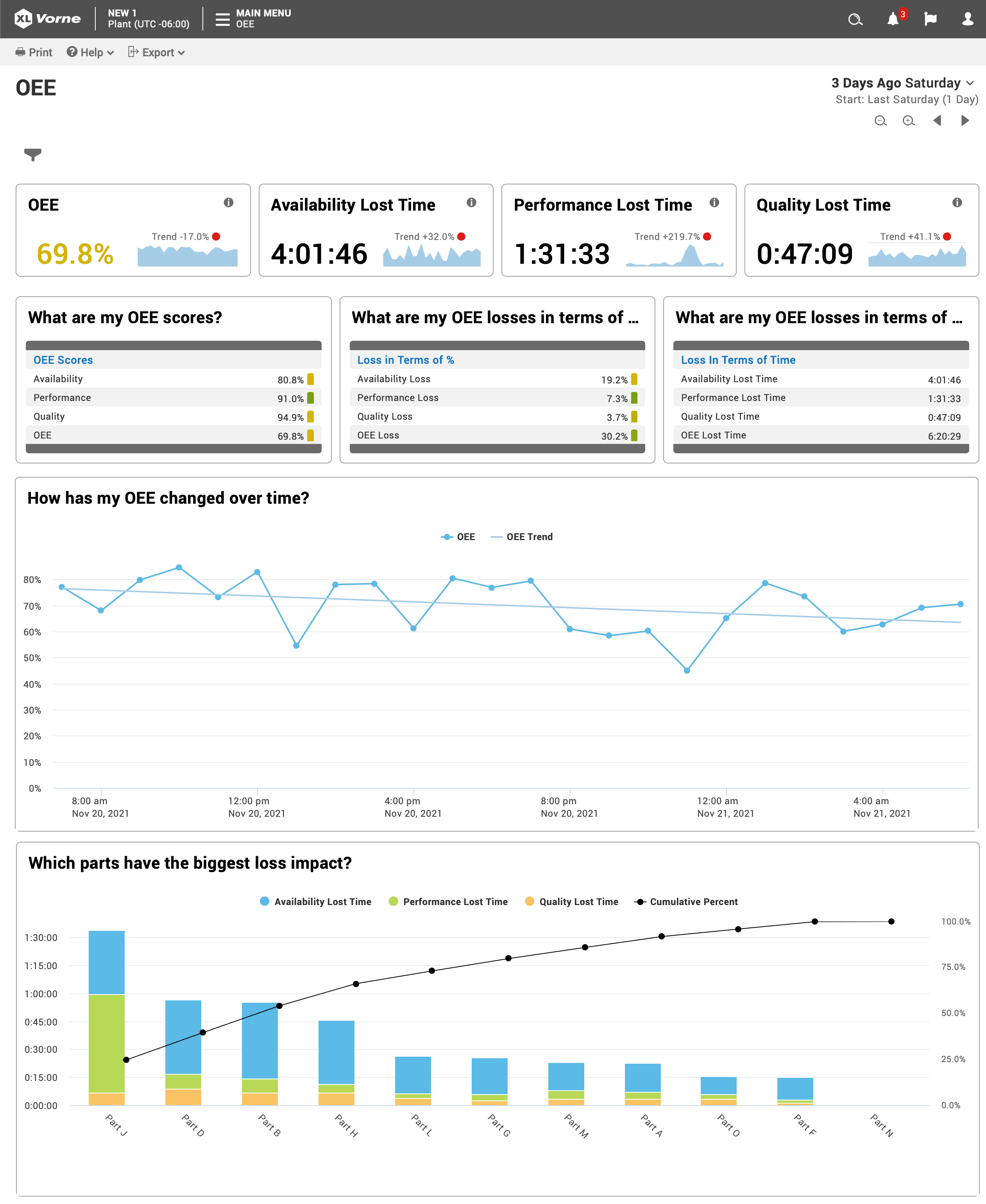

Your data. Your way.

Immediately leverage the data XL collects with built-in reports like OEE, Downtime, TEEP, Changeover, Top Losses, and Total Production Timeline. Even better – create custom dashboards, reports, and export files to organize exactly the information you want in exactly the way you want to see it. With over 100 metrics and more than 20 dimensions available in real-time and historically – you have a wealth of actionable information to mine. And your data is not locked in a silo – you can export it to Microsoft Excel with a single click.

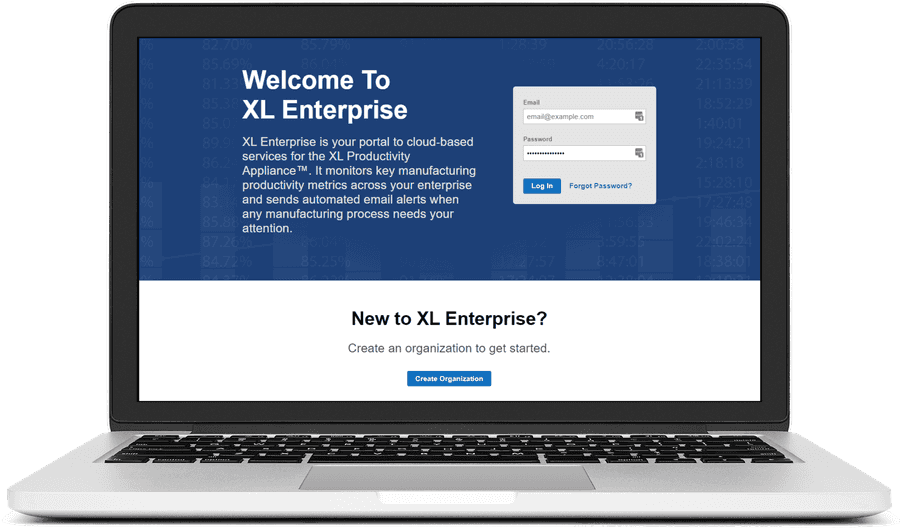

Instant alerts. Emailed reports. Automated updates.

XL Enterprise™ is the cloud component of Vorne’s Industrial IoT platform for manufacturing. It receives real-time production monitoring information from your XL Productivity Appliances™ to automatically:

- Send email and text message alerts based on real-time production metrics.

- Send alerts when your process stops, runs slow, nears the end of a changeover, has an OEE score below expectations, etc.

- Escalate issues from line-level personnel to your senior leadership team.

- Eliminate manual shift reporting with emailed shift reports.

- Update XL with new features as we release them.

Unlike most cloud applications for manufacturing, XL Enterprise™ is entirely optional, and many of its services are free. We completely understand that most companies don’t want to be locked into costly subscription-based services.

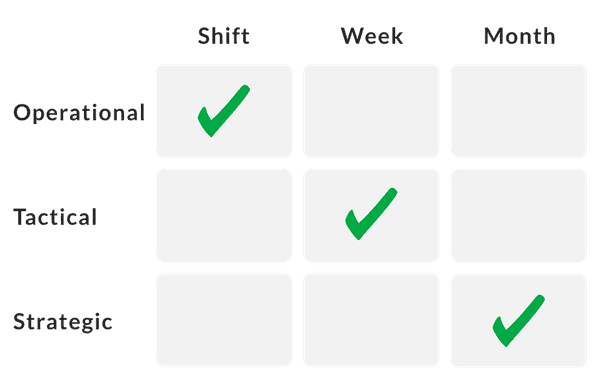

Drive improvement. At every level.

Operational. Tactical. Strategic.

XL provides you with a single source of production data. Detailed. Accurate. Timely. Precise. One data foundation to drive change across all roles and responsibilities.

- Operators focus on what they can improve in the next few hours. Get the line to speed. Quickly react to down events. Meet the changeover target.

- Supervisors focus on driving improvement across days or weeks. Analyze a problematic part. Set shift targets. Use data to be proactive – not reactive.

- Leadership focuses on change that spans months or longer. Launch a project. Set goals. Compare investment to results.

With XL – your data aligns your team. Naturally. Everyone works from the same set of information towards the same set of goals.

D.G. | Operations Manager | Grain Milling and Packaging Company

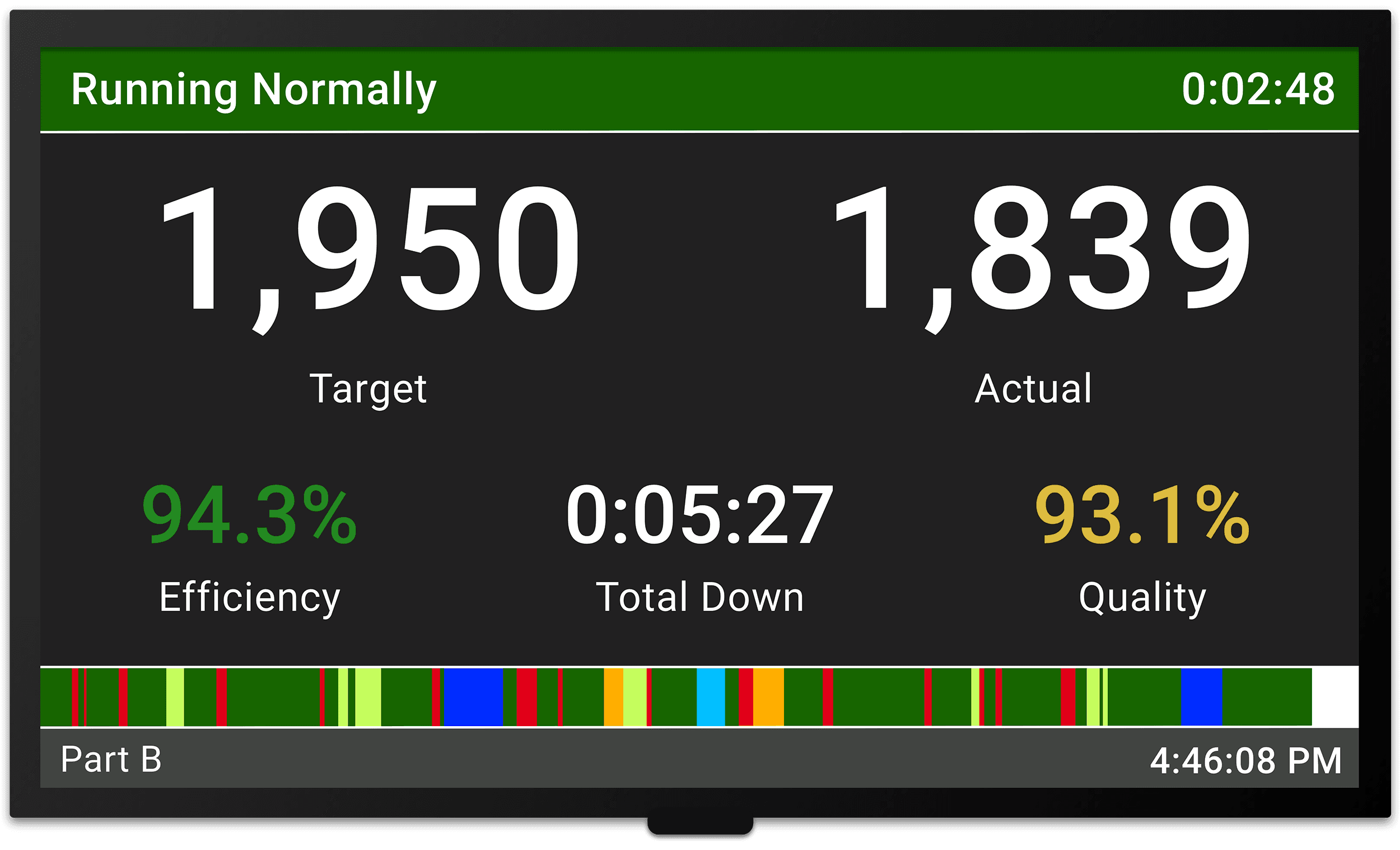

This shift. Empower operators.

Operational

Your operators need answers to two simple questions:

- What do we need to make this shift?

- Are we on target?

The XL scoreboard answers these questions in real-time. If Efficiency is 100% or better – your operators are on track to “win the shift”. We see time and time again that keeping things simple achieves better results. So keep it simple. Use the built-in scoreboard configuration or select from 100+ included metrics.

The scoreboard drives the first wave of productivity improvement with XL.

A.C. | Manufacturing Consultant | Manufacturing Consulting Firm

This week. Improve daily meetings.

Tactical

How do world-class manufacturing companies ensure their production meetings are effective? By basing them on accurate, actionable, up-to-date data.

- Are you relying on manually collected, inaccurate, or out-of-date data?

- Are decisions based on opinions – or data?

With XL you are just a click away from more effective daily meetings. Start with one of our built-in reports or create your own dashboard report.

Improved production meetings drives the second wave of productivity improvement with XL.

M.H. | Plant Engineer | Tier 1 Automotive

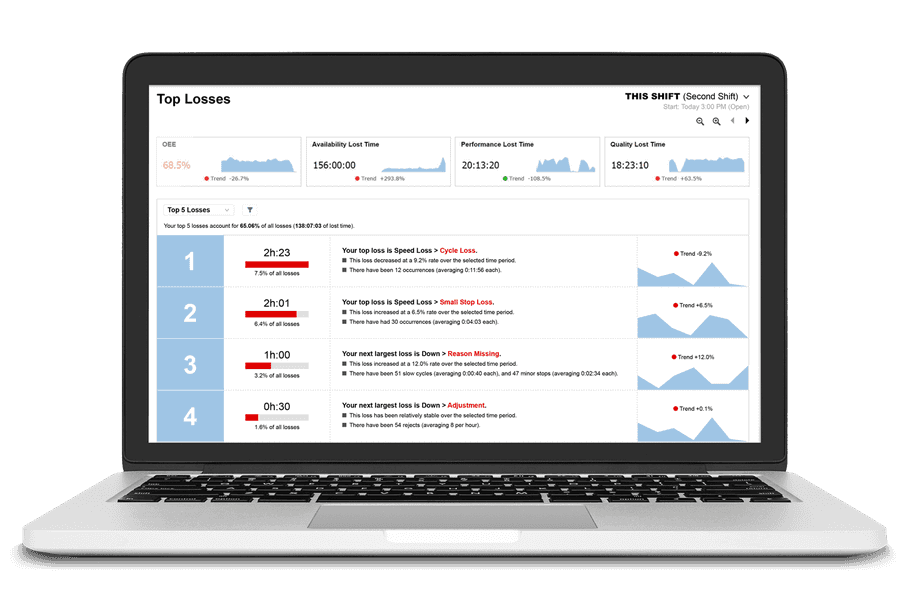

This month. Attack the right loss.

Strategic

Most companies try to accomplish too much and end up achieving too little. Why? They focus on the wrong things.

- Do you know your top 10 losses?

- Which are improving?

- Which are getting worse?

The XL Top Losses report ranks every loss in terms of time. Every down reason. Slow cycles. Small stops. Startup rejects. Production rejects. Changeovers. All ranked by impact and presented in one page. With trend information that instantly shows you where you are improving and where things are getting worse. Banish assumptions. Allocate resources where you will see the biggest improvement for the least effort.

Top losses and other analytics drive the third wave of improvements with XL.

W.M. | Operations Manager | Food Manufacturing Plant

We make it easy. For you.

Did you know that more than 1,000 companies have started their XL deployment with a free 90-day trial? In fact, we encourage every new customer to start with a trial. At the end of the day – what really matters is how well XL works for you. XL trials follow a simple 5-step process:

See. Talk one-on-one with one of our manufacturing experts about your process. We’ll show you XL and focus on your questions and your challenges.

Order. Provide a purchase order or credit card to start your trial. Pay nothing unless you keep XL.

Install. Our experts will guide you through installing and configuring XL using web applications and our trial roadmap.

Optimize. We’ll help you understand, interpret, and leverage all the new information and insights from XL to drive improvement and promote change.

Expand. Like XL? Take advantage of a special rollout discount to add XL to other processes in your plant. XL seamlessly scales from machine to enterprise.

J.C. | Engineering Manager | Wheel and Drive Manufacturer

Built on Best Practices

XL leverages the knowledge and expertise of the same team that writes and publishes OEE.com and LeanProduction.com. It thoroughly integrates a whole host of industry best practices including OEE, TEEP, Six Big Losses, Theory of Constraints, SMED, Continuous Improvement, and Short Interval Control. And it is designed to be easy. XL easy. Because a powerful product only creates change when it is used. By you.

Are you ready to create change?

D.G. | Plant Manager | Hospitality and Healthcare Products and Services