Production Monitoring and Tracking

What is Production Monitoring?

Production monitoring is the collection of data from the manufacturing process typically in real-time, to better understand and continually improve production efficiency and quality.

There are two fundamental aspects to production monitoring:

- The first is using data collection to create an accurate data foundation.

- The second is transforming that data into actionable information. It is essential to do both well in order to effectively improve your manufacturing process.

Decisions are the pivot between information and action, and they are arguably the most important aspect of production tracking. They are the point in time when information is reviewed, and a course of action is decided.

Production Monitoring and Machine Monitoring: Better Together

Production Monitoring and machine monitoring are closely related topics, so let’s explore how they relate to each other. We’ll start with brief definitions for each.

Machine Monitoring Definition

Machine monitoring is used to implement automated, real-time data collection for key equipment in your manufacturing process, such as the process constraint, to build an accurate and comprehensive data foundation (i.e., create a digital twin). Utilize that data to continuously improve machine operation and effectiveness.

Production Monitoring Definition

Production monitoring is used to transform an accurate data foundation that captures key metrics for each manufacturing process into a source of actionable information. Regularly review that information within a structured framework to facilitate decisions and actions that will improve your manufacturing operations.

Machine Monitoring and Production Monitoring both rely on:

i) data collection to create highly accurate data foundations and

ii) transforming that data into actionable information, which

iii) ultimately enables you to take effective actions to continuously improve your manufacturing processes.

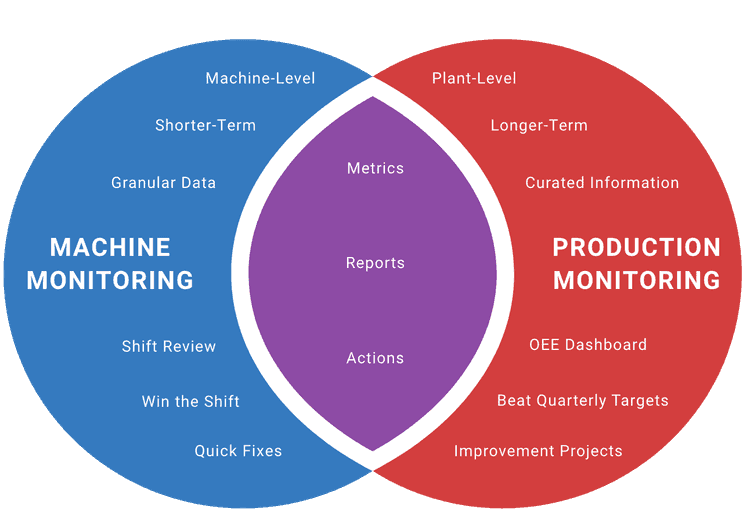

Where Machine Monitoring and Production Monitoring differ is in scope. The focus of Machine Monitoring tends toward specific pieces of equipment, granular data, and shorter time intervals. The focus of Production Monitoring tends toward the plant level, curated information, and longer time intervals. Here is a visual representation of commonalities and differences.

Why Use Production Monitoring?

Production monitoring enables you to make decisions based on an objective, fact-based view of your manufacturing operations. This is extremely important because manufacturing teams are often surprised, and sometimes even shocked when they gain an accurate understanding of losses in their manufacturing operations.

Chances are that you have a very good understanding of what you produce from monitoring your production output. Far fewer manufacturing operations have a firm grasp on what they could have produced and the actions they can take to produce more in the future. In other words, production monitoring enables you to move from the simpler question of “How much did I make this shift?” to the more complex question of “How can I best improve my process?“ This transition is also a key part of the value proposition of Industry 4.0 and digital manufacturing.

Production Monitoring and Losses

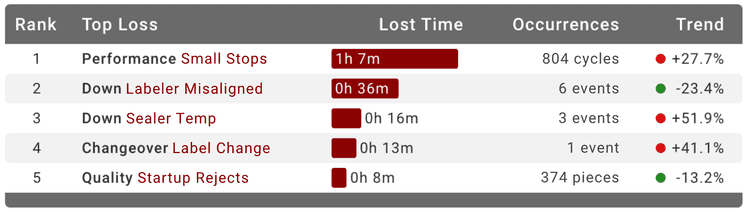

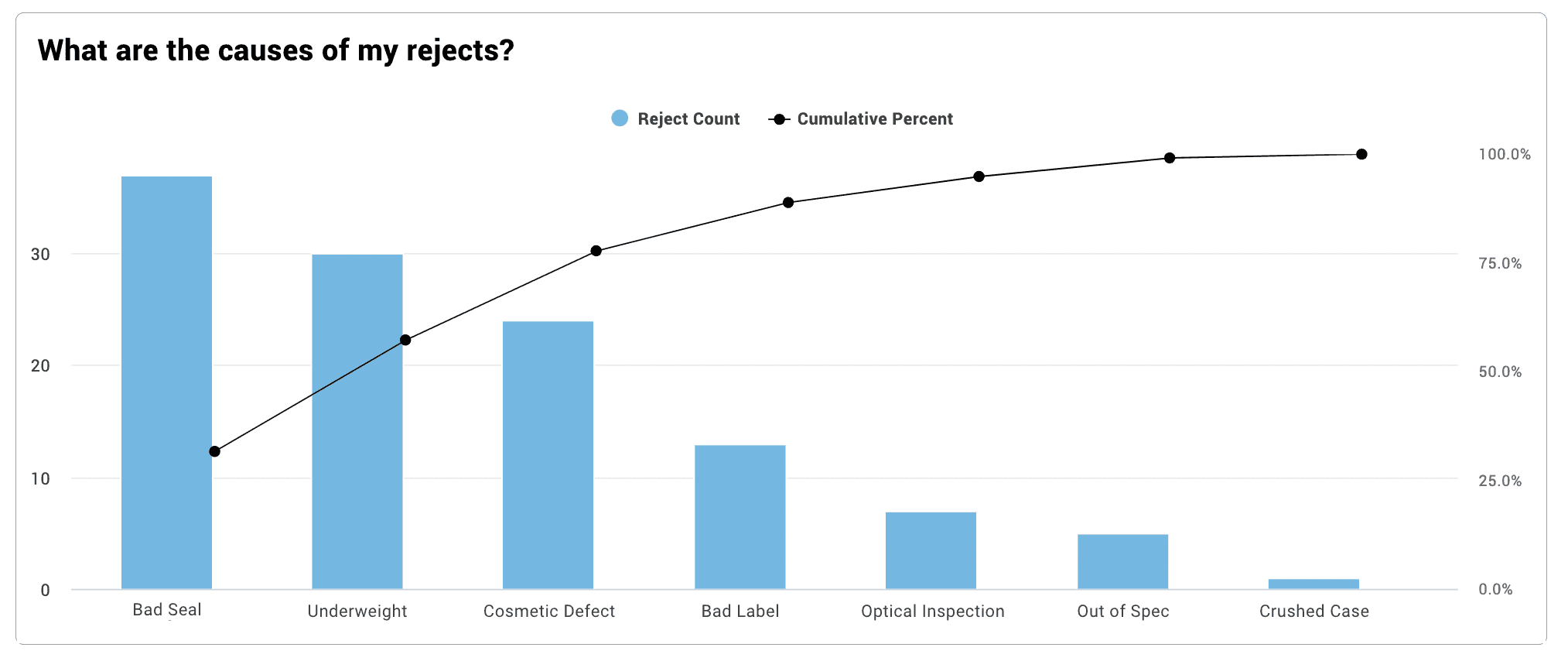

The goal is to thoroughly understand your losses and present them in a way that fluidly leads to insights on where to focus your time and attention. For example, a Top Losses report, like the following, is an excellent visual for transforming data into actionable information.

What is the Importance of Production Monitoring?

The true importance of production monitoring lies in taking effective actions toward long-term objectives based on shared information. It is much easier to make decisions that align with your company objectives when everyone has access to the same pool of trusted data. Sharing data has become much easier with the proliferation of technologies associated with Industry 4.0 and digital manufacturing.

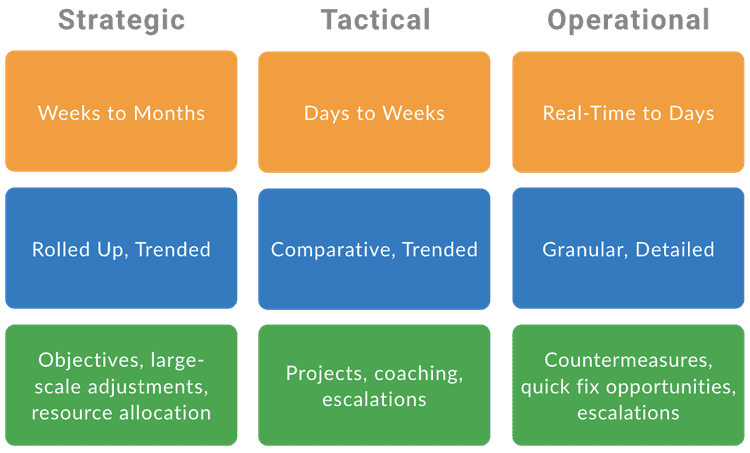

Let's explore how production tracking impacts and aligns every level of your manufacturing operation. Specifically, we will use the STO model (Strategic, Tactical, Operational) to explore how to drive improvement at every level.

Strategic Benefits of Production Monitoring

At the strategic level, the goal of production tracking systems is to provide a big-picture view. At this level, you want to focus on the forest, not the trees.

- Time frame is weeks to months. What happens on a day-to-day basis is best handled at the tactical and operational levels.

- Information is typically rolled up and trended. For example, viewing trends by department.

- Actions are broad in scope. Set large-scale objectives, ensure your team has sufficient resources to achieve them, and step in to make adjustments as needed.

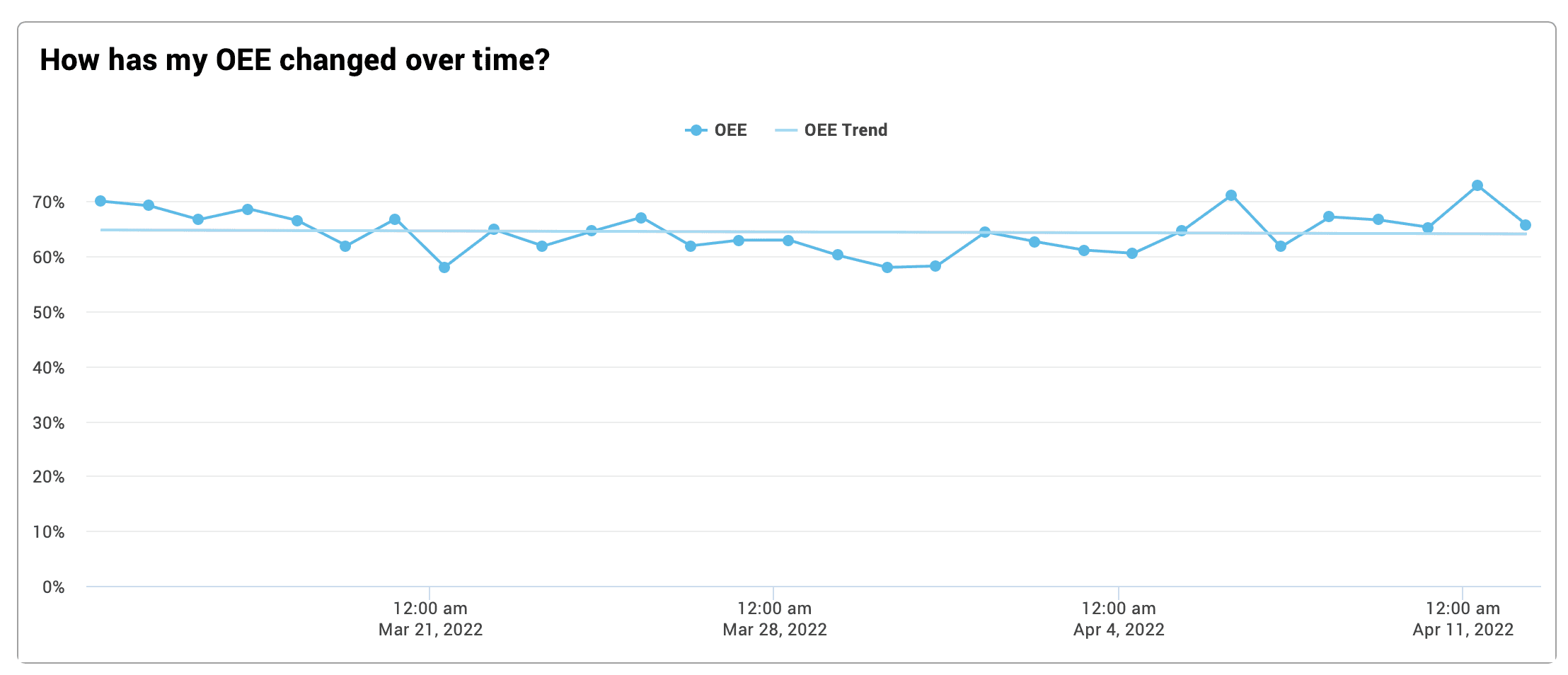

For example, viewing quarterly OEE trends by department is a suitable focus at the strategic level. Where there are challenges, delve into the tactical details with departmental managers. Where you are meeting or exceeding objectives, provide positive reinforcement for the entire team!

Tactical Benefits of Production Monitoring

At the tactical level, the goal of a production monitoring system is to translate strategic objectives into concrete actions.

- Time frame is days to weeks. This time frame is very compatible with iterative and agile projects, which we recommend for improvement projects.

- Information is typically comparative and trended. Comparative data helps identify opportunities for improvement by comparing what is working well with what is not (whether by shift, team, part, or production line).

- Actions are focused and specific. Use projects to address shortcomings with equipment and use coaching to address shortcomings with people.

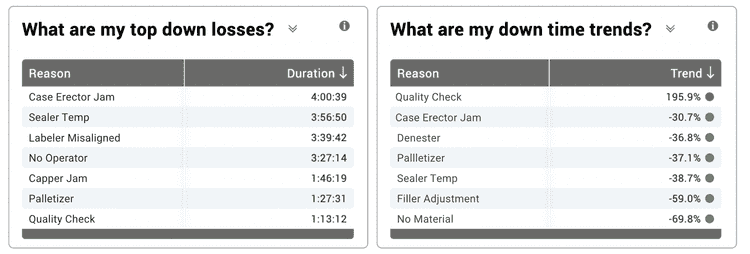

For example, downtime represents the largest loss for most manufacturers. Looking at comparative and trended data can help identify where to focus your attention. The following report snippet provides two loss perspectives: largest loss (Case Erector Jam) and emerging loss (Quality Check).

As another example, monitoring the quality of a product is also a key objective for manufacturers. Production monitoring software can utilize various data collection techniques to provide simple but actionable forms of quality monitoring as conveyed with this Pareto chart.

Operational Benefits of Real-Time Production Monitoring

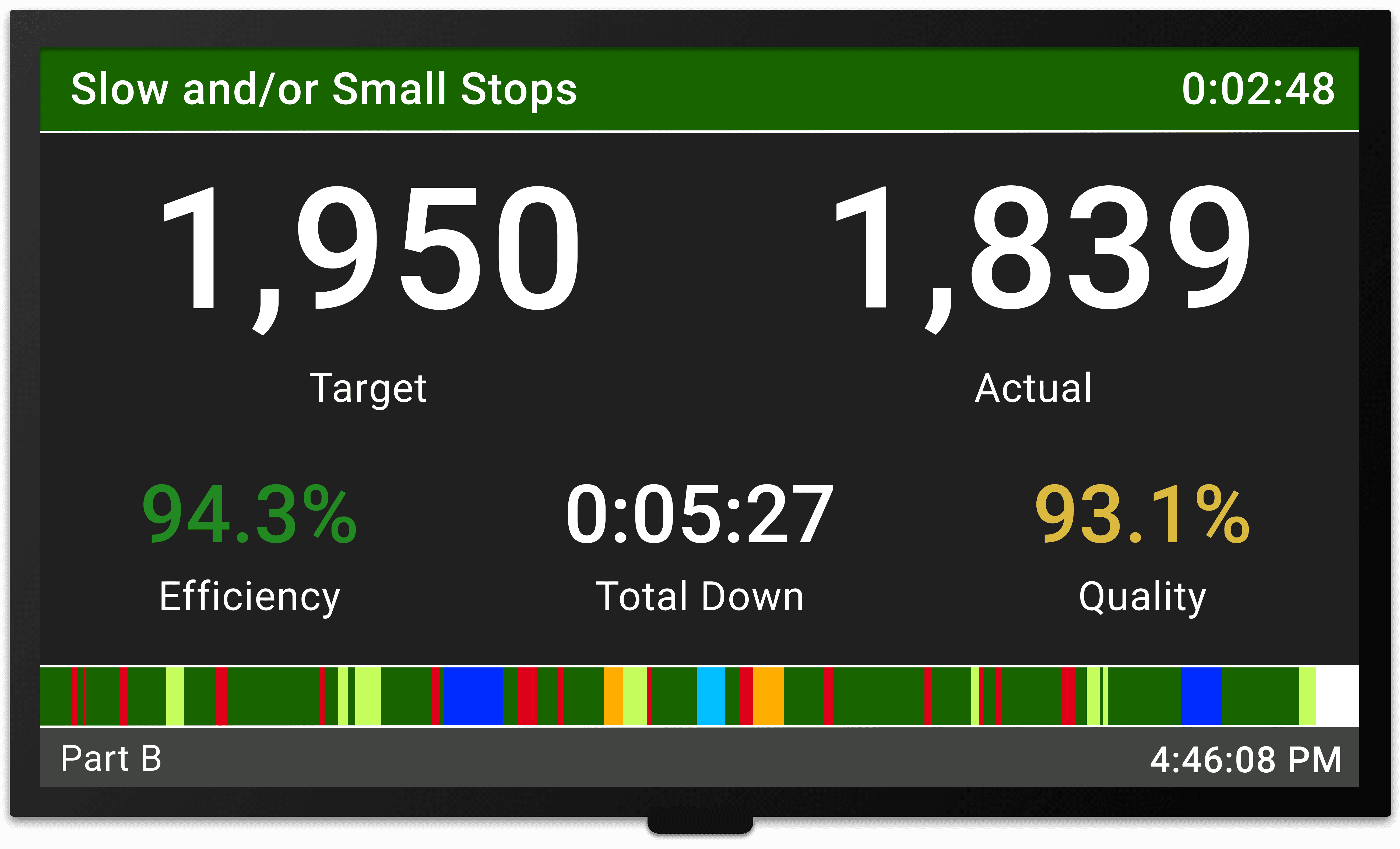

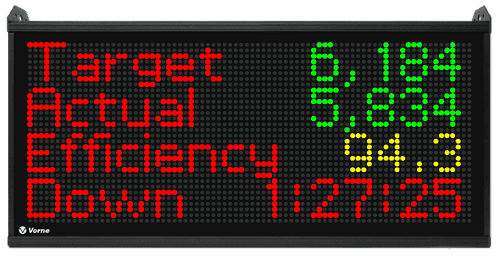

At the operational level, the goal of production monitoring systems is to significantly improve operators' ability to react to emerging issues on the production line. This is typically achieved through production monitoring display systems.

- Time frame is real-time to days. Harnessing real-time data enables and encourages operators to “win the shift.”

- Information is typically detailed and granular. Operators are directly responding to adverse events on the production line such as extended down events, clusters of small stops, and changeovers that are over target time.

- Actions are narrow in scope. At this level, actions tend to be reactive until operators are trained in more advanced and proactive methodologies such as Short Interval Control.

For example, operators will benefit from a real-time production monitoring system because it enables real-time data to be shown on the plant floor. Production monitoring display systems can provide significant value by delivering the right information at the right time - when your plant floor team can still change the arc of the shift.

Because operators tend to be focused on specific production lines, there tends to be quite a bit of overlap with machine monitoring at this level.

What are Some Production Monitoring Tools?

There is a broad range of tools that supplement and enhance production monitoring and tracking. A few of these include production monitoring display systems, production monitoring software, and frameworks such as Structured Improvement.

Production Monitoring Display Systems

Production display boards enable real-time production monitoring to directly benefit your plant floor team. Having production display boards on the plant floor provides operators with instant feedback on critical progress indicators and metrics. The goal is to equip operators with better tools to react quickly to emergent issues on the production line.

Production Monitoring Software

Production monitoring software takes data curation and analysis, often an intimidating and complex process, and simplifies it through advanced reporting and improvement tools. Built-in pages and reports provide instant views of your production data that are ready for your analysis as soon as you begin collecting data. Customizable dashboards provide you with the flexibility to view your data exactly how you want once you are comfortable with exploring built-in reports. Learn more about OEE Software and how it helps simplify and amplify your production monitoring efforts. Effective production monitoring software empowers you to focus your time and energy on taking action as opposed to figuring out what and where you need to improve.

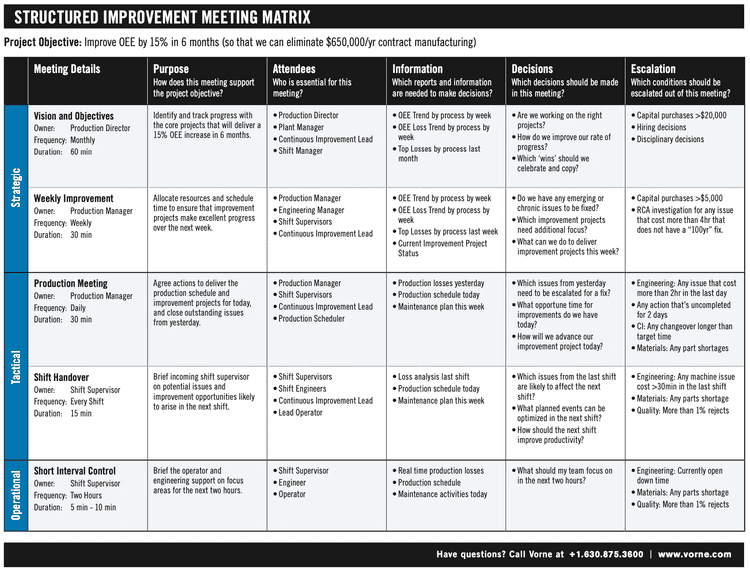

Structured Improvement Model

The goal of production monitoring is to take action to improve your operations. Aligning objectives, information, and actions across levels will amplify their effectiveness. This is the role of Structured Improvement.

Structured Improvement is a tool to align people, information, decisions, and actions towards a common set of objectives. It involves three steps:

- Define your objective(s)

- Define and connect supporting meetings

- Define and connect supporting reports

In other words, define an improvement objective, define the smallest number of connected meetings that will effectively drive meaningful and aligned action, and define supporting reports appropriate for each level that will expose the information needed to drive effective actions toward the objective.

Get Started with Structured Improvement

Start A Free Production Monitoring Trial Today

With the Vorne XL Productivity Appliance™ you can:

- Win the shift by motivating your operators with real-time targets on a plant-floor scoreboard

- Instantly access 100+ real-time and historical metrics, including OEE, Six Big Losses, and TEEP

- Provide supervisors and managers immediate insights with 50+ out-of-the-box reports

- Present information exactly as you want it with an unlimited number of custom reports

- Push alerts and reports to key individuals to deliver the information they need when they need it

- Automatically escalate to proactively call attention to emerging issues

The Vorne XL Productivity Appliance™ is an industrial IoT (IIoT) device that delivers all of this and much more. Our most popular model is $3,990 and includes unlimited users, free software updates, free technical support, and an industry-leading 3-year warranty. There are 42,000+ XL installations across 45+ countries, and we encourage all new applications to start with a free 90-day trial. Book a one-on-one webinar and one of our product experts will be happy to explore your application.