Visual Factory

What Is the Visual Factory?

Visual factory is a term used to describe how data and information are conveyed in a manufacturing environment. In a lean manufacturing environment, time and resources dedicated to conveying information, although necessary, are a form of waste. By using visual methods to convey information, such as signs, charts, and Andons, information is easily accessible to those who need it. The current status of all processes is immediately apparent.

Visual Factory in Lean Manufacturing

The more complex any process becomes, the more critical information exchange is to the process. Visual factory is a set of tools that allow for accurate and efficient information conveyance. Visual factory is implemented in two stages – determining what information needs to be communicated and how this is accomplished.

Determining what information needs to be conveyed is the starting point of visual factory. The current state must be compared to the future state goals in order to determine what information is to be delivered. The information required to get from one state to another is what must be conveyed. How the information is conveyed depends on the desired end result. The location and method of information delivery also depend on the relevancy of the information. Typically this data includes:

- Process metrics

- Work instructions

- General plant information

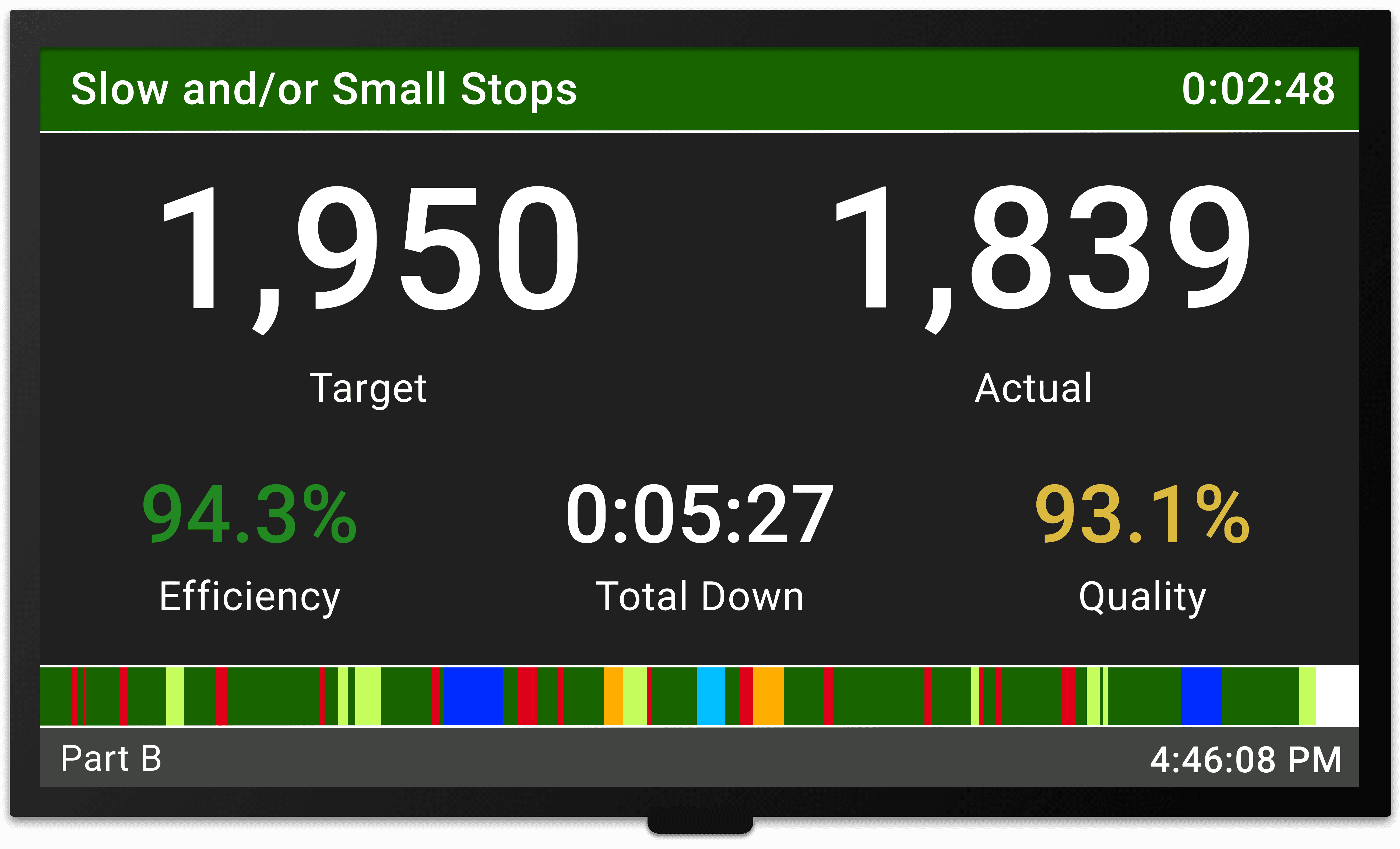

Process metrics are typically displayed at the machine or cell. This information is most effective when it is delivered in real-time. Immediate feedback facilitates immediate improvement. When lights are used to indicate information, it is referred to as an Andon. Andons are often the centerpiece of the visual factory because of the tremendous real-time process information that they convey.

Work instructions are typically posted in the production areas. Highly visual instructions with photographs and graphics will generally minimize production errors. The more information can be conveyed visually, the more it will improve communication.

General plant information is typically posted in a central location where everyone has access to it. Lean manufacturing relies on bi-directional information exchange throughout the organization. In a visual factory environment, information is delivered to inform, alert, and motivate.

Benefits of Visual Factory

Efficient, timely communication allows organizations to function at their full potential. When all employees are aware of what they need to do, as well as when and how they need to do it, they are able to perform their jobs more effectively. Providing visual information to factory employees provides the following benefits:

- Reduce errors

- Increase employee morale

- Increase machine uptime

- Increase machine run rates

- Decrease WIP (Work In Progress)

Visual factory Allows Companies to communicate and provide world-class performance.

1. Reduce Errors

One of the most common sources of error in manufacturing is human error. Including posted work instructions, images, or checklists for complex tasks helps ensure no steps are forgotten or performed incorrectly. This not only creates a more efficient workplace but a safer workplace, as well. The clearer the instructions are, the less room there is for error.

2. Increase Employee Morale

Providing simple, well-placed visual instructions for complex tasks gives employees confidence in their ability to successfully do their jobs. Additionally, having visual, real-time data on the plant floor motivates operators to reach shift targets by giving them instant feedback on their progress. It also empowers them with the information they need to make adjustments to their actions during the shift rather than finding mistakes after the fact.

3. Increase Machine Uptime

Visual information can serve as a quick reminder of steps to a process rather than expecting employees to memorize them perfectly. This means that processes such as changeovers, maintenance, and others during which machines would normally be down can be completed more quickly. As a result, machine uptime will be significantly higher, raising your OEE Availability.

4. Increase Machine Run Rates

Providing quick visual cues that operators can use as reminders, like a color-coded calendar for scheduling machine maintenance, enables them to prevent problems like machines that underperform due to wear. Further, employees make fewer mistakes that can slow down production, such as misfeeds, when they have clear visual instructions as to which materials are optimal to use in each machine. As a result of creating a visual factory, run rates will be significantly higher, raising your OEE Performance.

5. Decrease WIP (Work in Progress)

When a factory uses visual production cues such as a whiteboard or scoreboard, it is important to focus measurements and visualizations on the constraint of the manufacturing process. By focusing on the constraint, it is much easier to see what actions need to be taken in order to improve flow at the constraint and decrease the amount of WIP inventory. This is especially true because the constraint is often where WIP inventory accumulates.