What's New With XL?

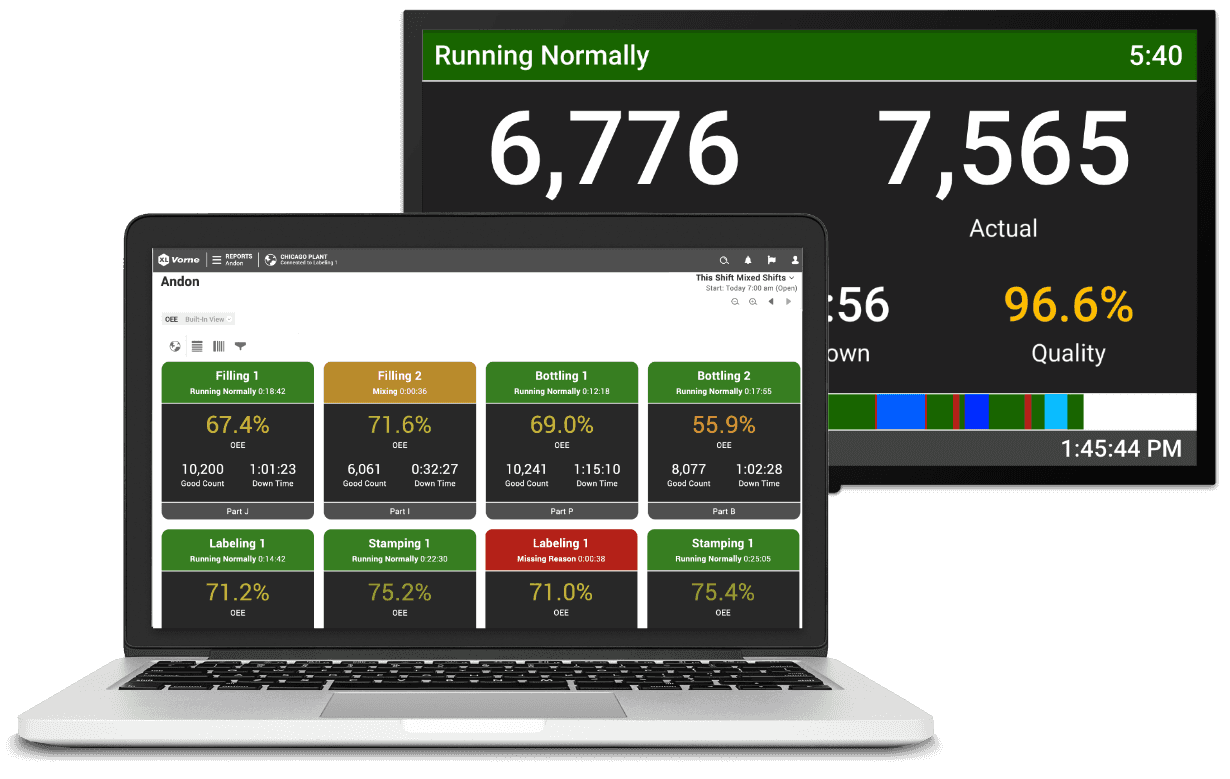

XL integrates hardware and software into one seamless package to drive improvements in manufacturing productivity, including highly accurate production data collection and a real-time plant floor display to inform and motivate your operators.

The most important feature of XL is EASY. Our goal is nothing short of making it incredibly easy for you to collect key real-time production data and improve your manufacturing productivity.

Our newest software (version 2.0 and higher) runs on an entirely new hardware platform, explicitly designed for the manufacturing industry, with an order of magnitude increase in processing power and an entirely redesigned data model. Compare versions, view the latest XL software release notes, read about the latest features below, or read about older software releases here.

2.21 (PRODUCTION)

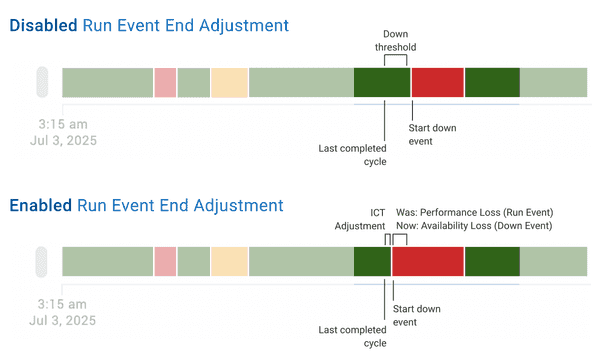

Run Event End Adjustment

Your data. Clean and pristine.

We’ve been doing lots of behind-the-scenes work with the XL production monitor - architecting and building a very powerful next-generation engine to support new features. One such feature is a new form of automatic data adjustment - transferring down detection time from the Run event to the Down event. Let’s explore this in depth!

This feature automatically adjusts the boundary between each Run and Down event, such that the Down event starts after the last cycle of the Run event. In other words, the down detection time (down threshold) is moved from the Run event to the Down event.

XL intelligently leaves enough time at the end of the Run event to ensure the partial cycles at the beginning and end of the Run event are always at least equal to one ICT (one cycle). In the diagram, this is represented by ICT Adjustment. The ICT Adjustment is always between 0 and the ICT (depending on how much time there is before the first cycle of the Run event).

This feature does not change your overall OEE score. It simply recategorizes time from an OEE Performance loss (the Run event) to an OEE Availability loss (the Down event) to better model what is actually happening on the production line.

Run Event End Adjustment (REEA) is automatically enabled for new units and can be optionally turned on for existing units at Settings > Parts and Run States > Run States.

TV Mode

Your favorite report on the big screen.

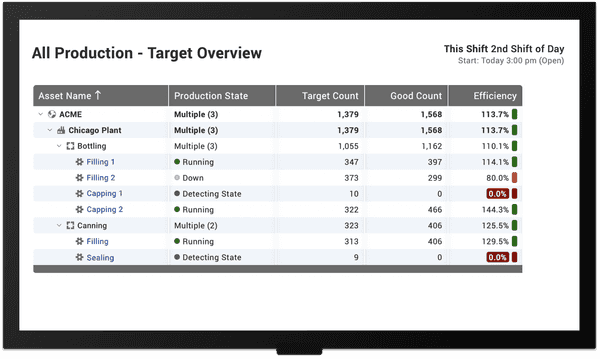

Many XL users already show their favorite report or dashboard on a TV for all to see. Now we have made it even easier with the all-new TV Mode. Display a focused, extra high-resolution view of the XL web page interface on a TV to see the data you want, where you want, with no distractions. Craft your ideal dashboard, choose your most used built-in reports, or simply showcase a web-based view of your scoreboard to align your entire team with what’s happening on your shop floor.

Simply type “?tv_mode=1” after the IP address in your browser to switch the WPI into a streamlined view ideal for display. TV Mode hides the App and Page Bars, alerts, footer, and most controls.

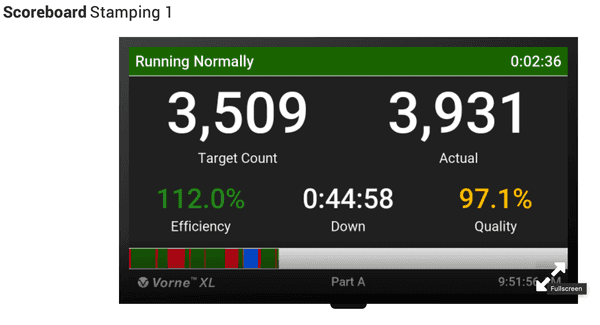

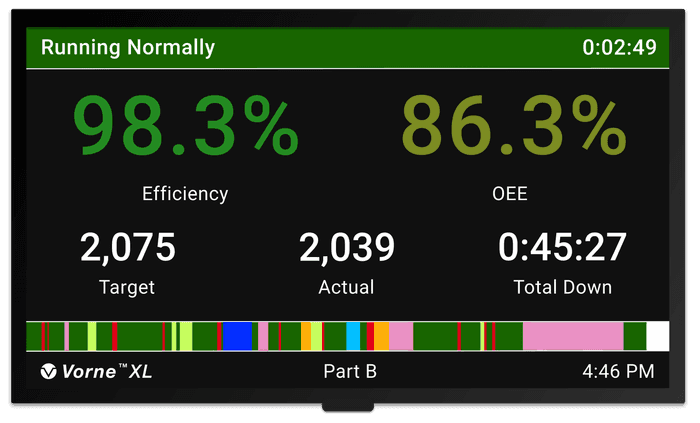

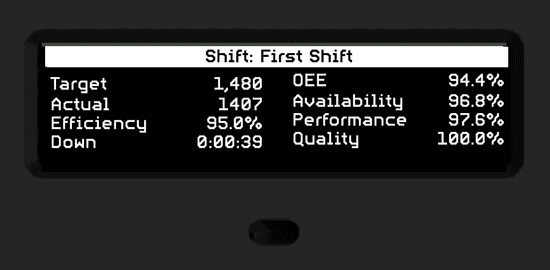

HD Scoreboard Anywhere

More of what you love.

Users love the XL HD scoreboard - so much that they want to see more of it. Now you can see it in your browser, and with the new TV Mode, on network-connected TVs. Simply navigate to Reports > Scoreboard to see it in action!

Reuse Dimensions in KPI Groups

One dimension. Many metrics.

Visualize multiple metrics for the same dimension within a single KPI Group. For example, compare each of the Six Big Losses by Shift, or OEE Factors by Part, all within the same KPI Group widget. Understand the context of your data in an instant.

Celebrate Wins

Visualize a job well done.

By popular request we added an XL800 (prior generation) feature to the XL810. Fireworks!

Motivate your plant floor team by celebrating success. If Efficiency meets the “good threshold” at any point during the last ten minutes of the shift, you can show congratulatory fireworks and “Great Job, Team!" on the XL810 scoreboard to recognize your team for their win!

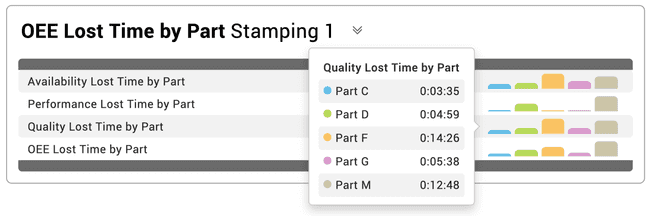

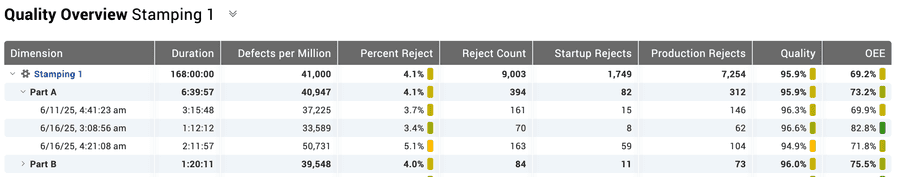

Defects per Million

A new perspective on defective.

Let’s welcome a new metric to our 140+ member family - Defects per Million. This is especially useful in industries where defect counts are typically very low, but still of paramount importance, such as PCB assembly. Defects per Million provides an additional perspective on quality by presenting it in terms of reject pieces per million total pieces. Technically this feature snuck its way into XL 2.20 - but we didn’t tell you about it!

2.20

Down Reasons

More reasons to take action.

We’ve added a new color to our palette: Pink! In the Chronogram, Event List, and Table widgets, pink indicates down events where no reason has been provided. Your plant floor team will see pink, too - right in the timeline of your XL HD scoreboard, anywhere a down reason is missing.

You can now disable the missing reason prompt for your scoreboard, which we recommend if your operators are not responsible for adding reasons. Plus, you can also change the default down reason if you prefer something other than Missing Reason.

With 2.20, it’s easier than ever to build an outstanding and actionable data foundation! Which brings us to our next new feature…

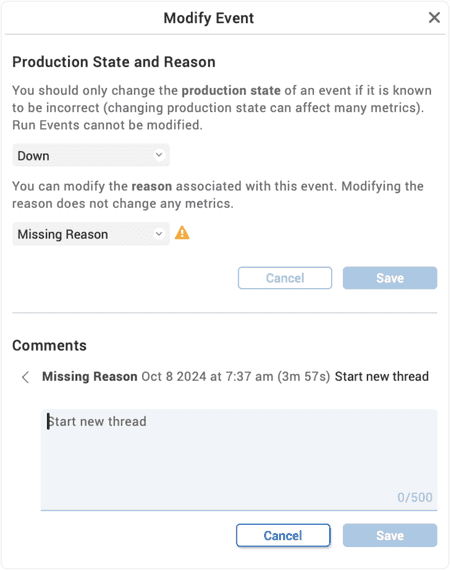

Easy Entry of Reason, Production State, and Comments

Your data… not set in stone.

You can now modify production states, and add or modify reasons and comments directly from the Chronogram, Event List, and Table widgets.

For Chronograms, click on the event. For Event Lists and Tables, click on the vertical ellipsis to open the Modify Event dialog.

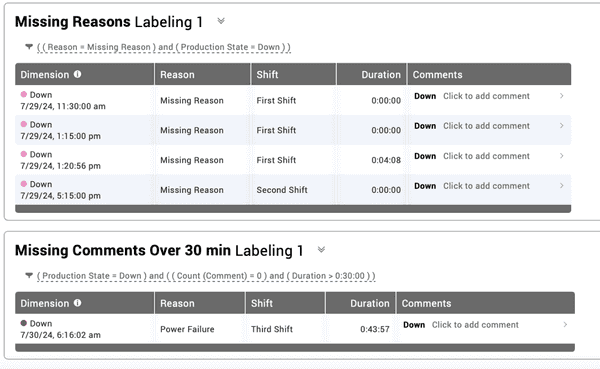

Audit Key Down Data Points

Your data completion hub.

Another way we’re helping you improve data completeness is through the new, built-in dashboard called “Audit - Down.” We’re making it super easy to:

- 1. Quickly identify and update down events that are missing reasons.

- 2. Add missing comments for long down events.

We recommend setting a policy that all down events longer than, say 30 minutes, should have an associated comment to capture context and insights.

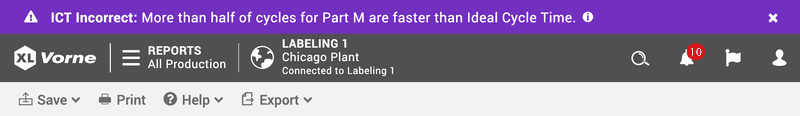

Urgent Data Quality Notifications

Three common problems, one common solution.

Three of the biggest problems we see when auditing customer data are part runs configured with an incorrect Ideal Cycle Time, or the manufacturing process running with no Shift or Part ID. So, we elevated those three scenarios where they won’t be missed!

You’ll see an urgent data quality notification if XL detects one of the three scenarios mentioned above. XL will also notify your plant floor team of the urgent data quality issue via the XL scoreboard.

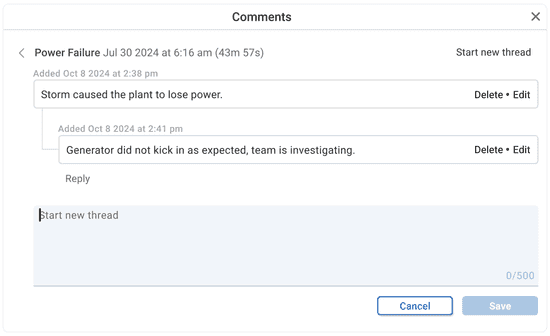

Enhanced and Expanded Comments

Thread your thoughts together.

Comments in XL are refreshed and refreshing, including updates to the Discussions UI, which is now called Threads.

You can also now use the filter live control in Tables and Event Lists to differentiate between events with and without comments - which is exactly what we do with the “Audit - Down” dashboard discussed above. Simply open the filter control and search for Count (Comments) in the Metrics section.

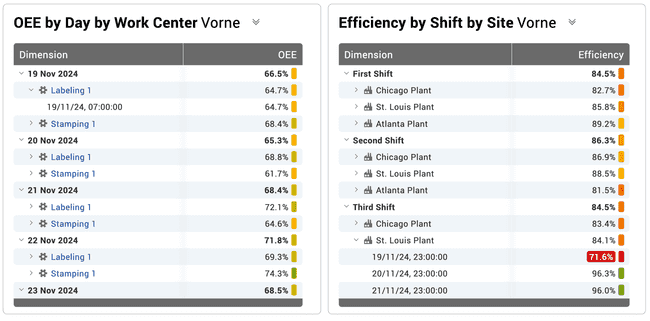

More Flexible Dimensions

Bring order to reports.

Congratulations to Production Day on becoming a full-fledged reporting dimension! Previously, you could create reports that aggregated data based on Day of Week, and you could create reports with date and time as a dimension. Now you can also create reports that explicitly aggregate data on single-day boundaries. Production Day is similar to a calendar day, except its boundaries align with your shift schedule, which is very helpful for reporting.

Enterprise Dimensions like Work Center previously had to come first in reports. Now they can go just about anywhere in the dimension hierarchy. For example, you can create a table of OEE by Day by Work Center or Efficiency by Shift by Site.

Faster Page Loads

Quick as a magic trick.

With some behind-the-scenes magic, such as virtual pings, progressive page updates, caching state, and more, report pages load faster. This is especially noticeable in environments where an XL device might be powered off or otherwise inaccessible on your network.

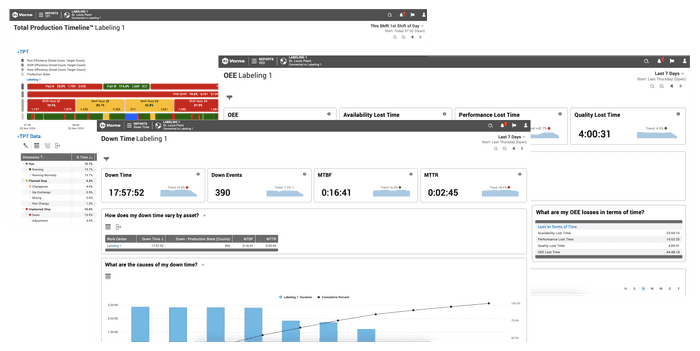

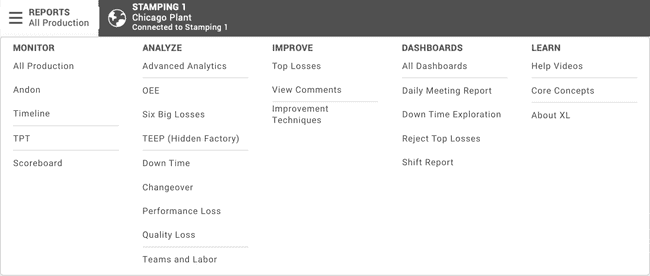

App Bar and Navigation

Just look up.

The Reports menu now places Dashboards front-and-center and all in one place. After all, they are the key to viewing your data your way.

Right next door, the App Bar now displays the name of the XL device to which you’re connected. This is especially useful when making data modifications that require you to be directly connected to the device for which you are changing data.

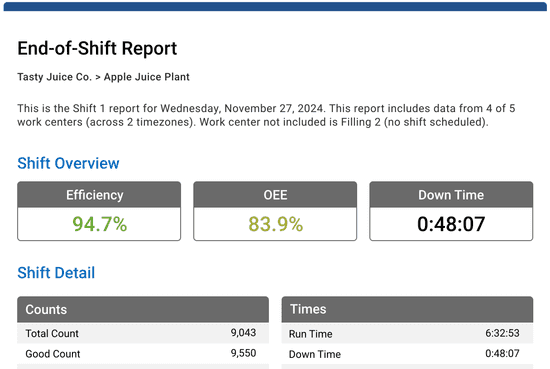

Email Reports

And more.

We worked behind-the-scenes to ensure that end-of-shift reports get sent from XL Enterprise as quickly as possible - as soon as all scheduled shifts are complete.

Additionally, XL will only capture unscheduled production as an unknown shift or part run when it detects that the process is definitely running. And, if XL does detect an unscheduled shift, it won’t group it with scheduled shifts in email reports and chronograms.

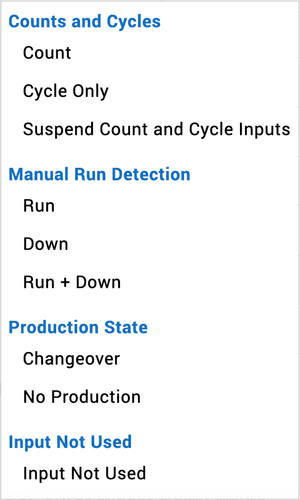

Digital Inputs

Input options. Uninhibited.

We’ve expanded what you can do with digital inputs - and made them easier than ever to configure. Options are categorized in three groups: Counts and Cycles, Manual Run Detection, and Production State. Plus, we added four brand-new options: Cycle Only, Run, Down, and No Production.

We also added a selection to automatically adjust input inhibit times based on the Ideal Cycle Time. This is handy if you have a wide variance in cycle times. And if you do happen to have very long cycle times, you can now enter inhibit times as long as one hour.

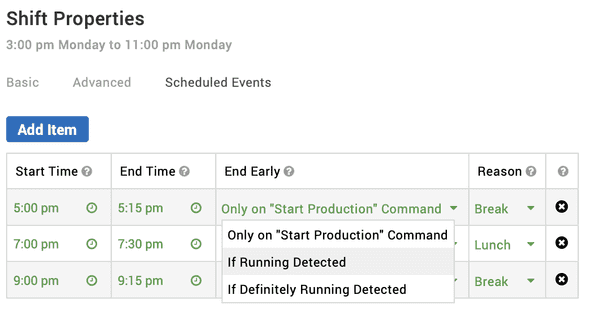

Time Schedule Events

Hit the ground running.

You can now configure scheduled events to end early if XL detects that the process is running or definitely running.

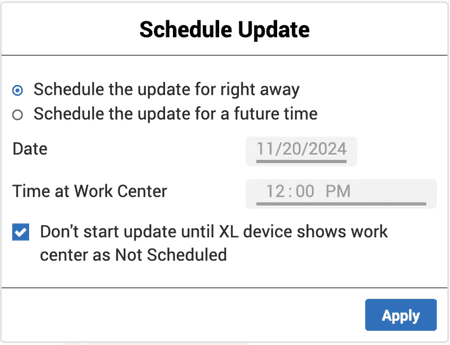

Managed Software Updates

Set it and forget it.

You can now centrally manage software updates in XL Enterprise for all of your XL devices (running version 2.19 or later).

You can configure a software update to begin right away, or to occur later, at a time of your choosing. In either case, you can also specify that the update not start for a given XL device until production is Not Scheduled.

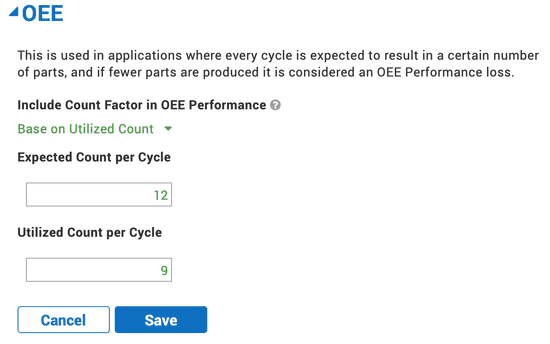

Count-Based OEE Factor

Fine-tune OEE for multi-up applications.

The world of OEE in manufacturing is vast, which is why we’ve added an optional new factor into the OEE Performance calculation - based on the expected number of counts per cycle.

For example, an injection molding tool might be expected to produce 12 parts with each cycle, however due to a damaged tool, 9 cavities are utilized and 3 are not. In this example, the OEE Performance Count Factor would be calculated as 75%.

Improved Gesture Recognition

Swipe right on XL.

It’s easier than ever to see your data at a glance with improved gesture recognition and faster screen response time for the XL HD.

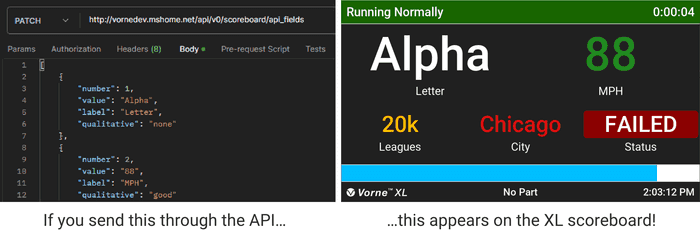

API Access for Scoreboard

Your plant-floor centerpiece.

The XL HD and XL810 scoreboards provide a flexible canvas for displaying data, so we added API access to enable integrating information from other sources into your plant-floor scoreboard view.