What Is XL?

Your All-In-One IIoT Platform for Improving Manufacturing Productivity - OEE, Downtime, Cycle Time, and so Much More

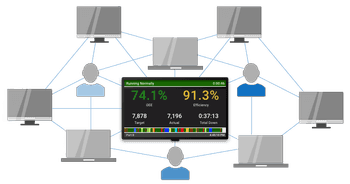

Monitor any machine. Any process. Anywhere.

We’ve done it 42,000+ times.

By connecting just one or two sensors to your line, Vorne XL automates data collection and provides real-time and historical visibility into your process with 140+ metrics, 64+ built-in reports, and unlimited custom reports. It integrates with your existing systems. And, all it takes is 8 hours to get up and running.

Watch a Video About XL

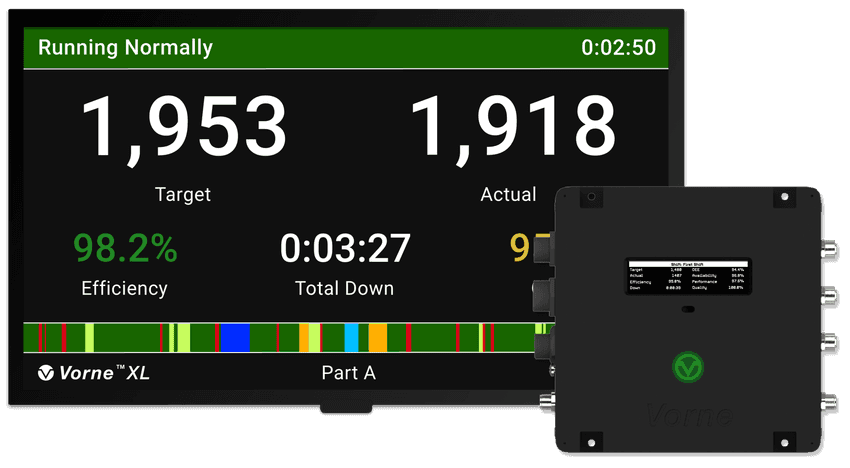

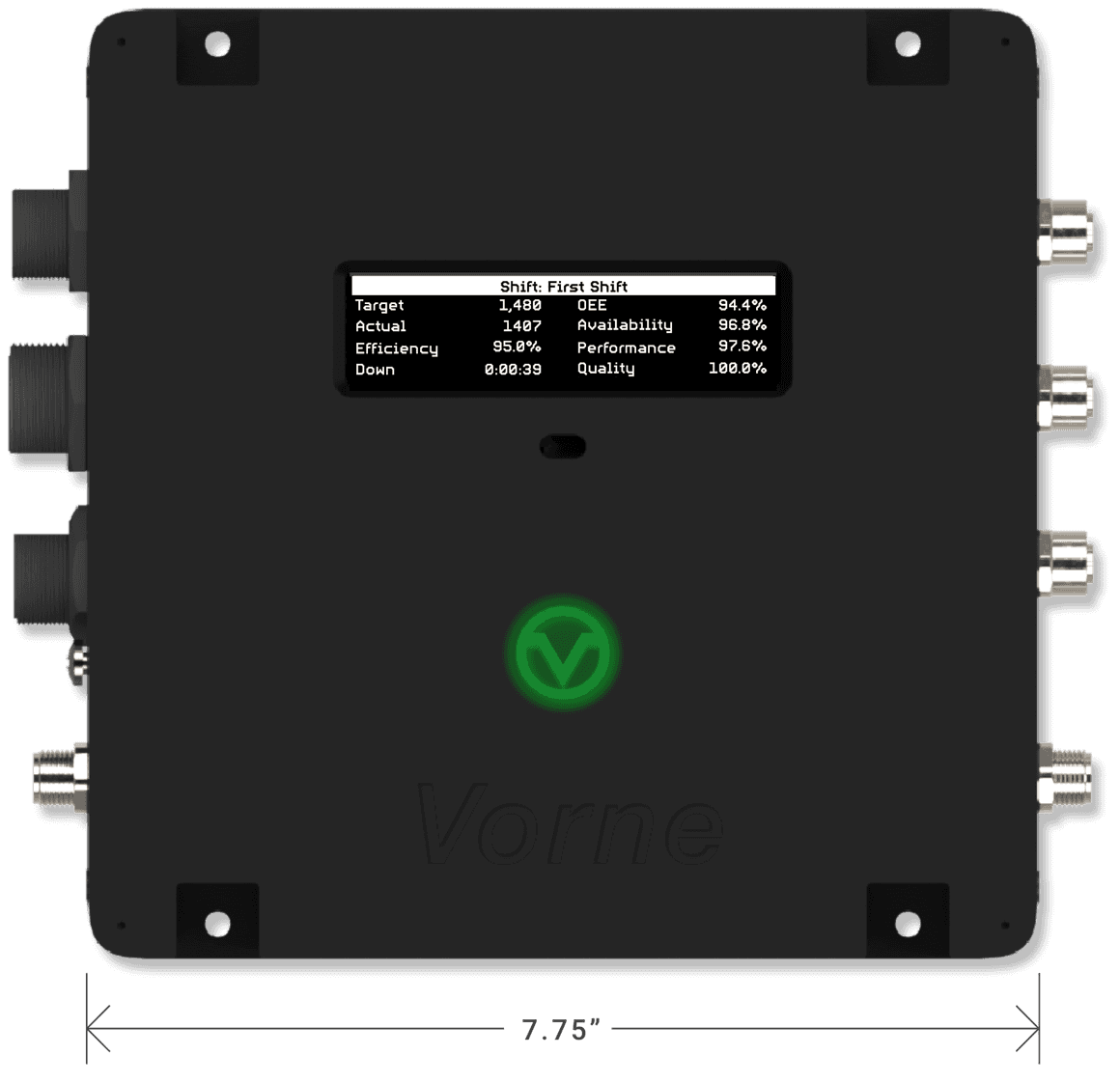

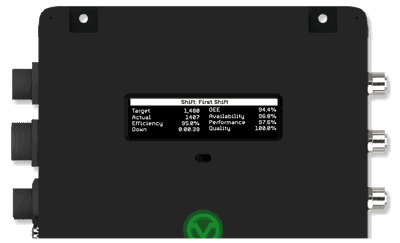

This is an XL Device

Looks smart. Acts even smarter.

XL is a sophisticated, fully-integrated edge computing device that includes:

- 1. Production monitor,

- 2. Built-in database,

- 3. Powerful browser-based reporting suite, and

- 4. Plant-floor visuals for operators.

| What’s Included in XL | What You’ll Need |

|---|---|

| XL Productivity Appliance | One or Two Sensors |

| Power Cord | Ethernet Cable |

| XL Barcode Kit (Optional) |

It contains everything you need to monitor and improve production. Simply plug it in and get started!

Start Your Free 90-Day Trial

This is How XL Works

As easy as 1, 2, 3.

We call it XL Easy for a reason:

1. Power

Connect XL to power.

2. Digital Input

Hook up one or two sensors or tap into an existing photo-eye, relay, PLC, or proximity switch.

3. Network

Connect XL to your network. Access everything through your browser.

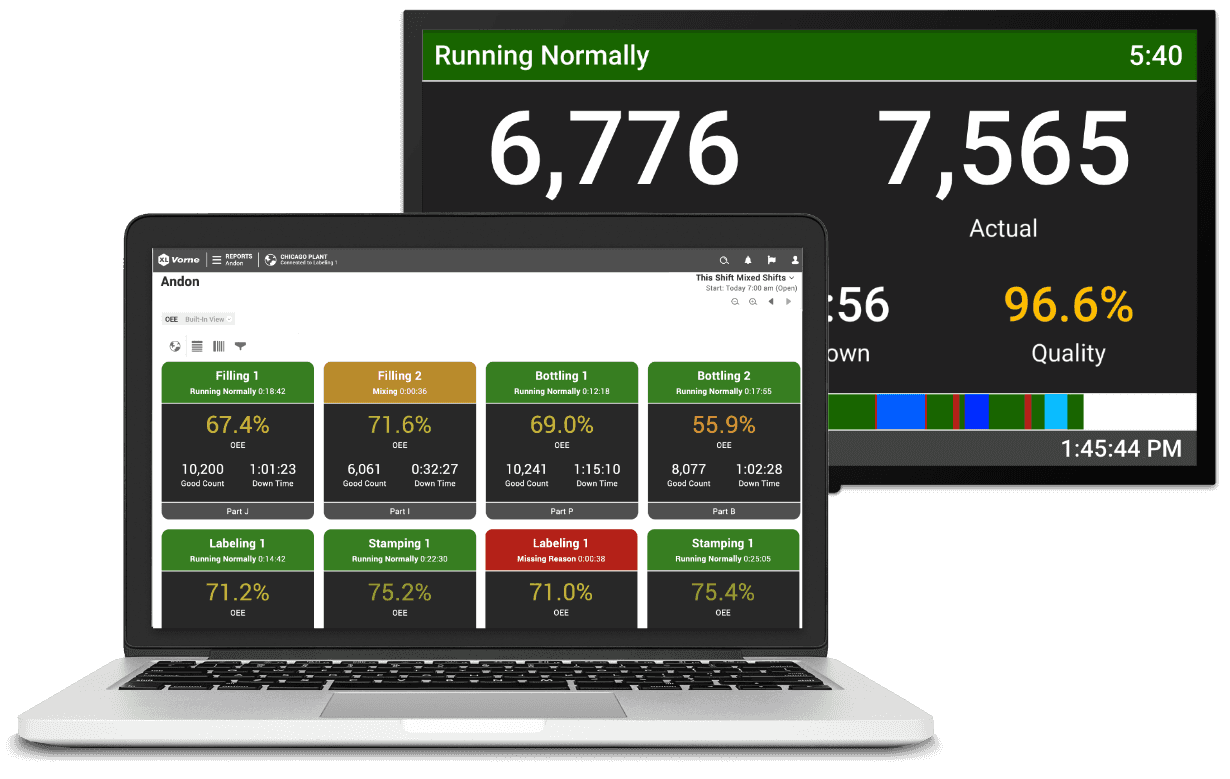

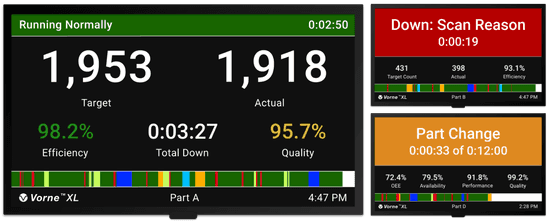

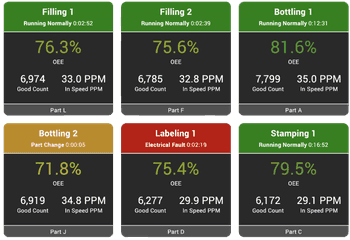

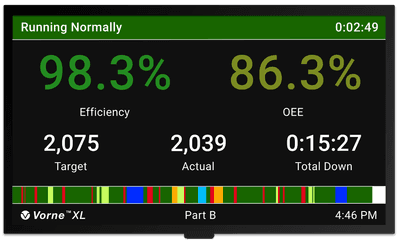

This is What Your Operators See

Win the shift, again and again.

This is an example of an XL plant-floor scoreboard.

It motivates your operators with real-time data so they can benchmark progress and instantly react to issues during the shift.

The scoreboard enables operators to take control and win their shift!

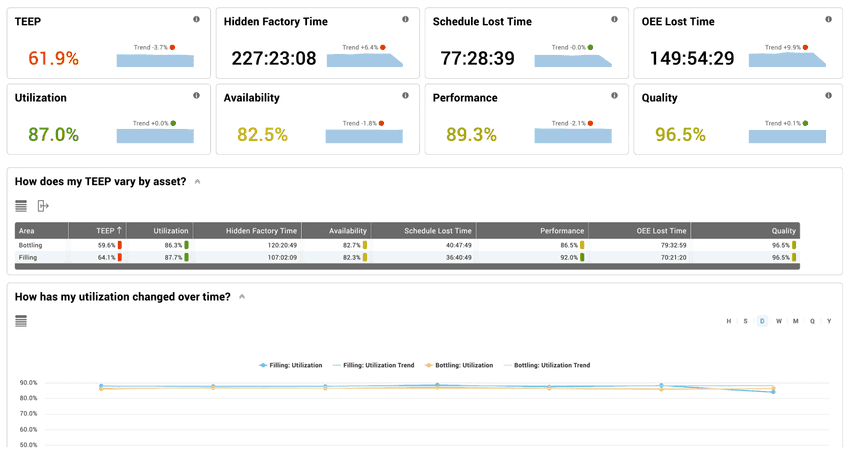

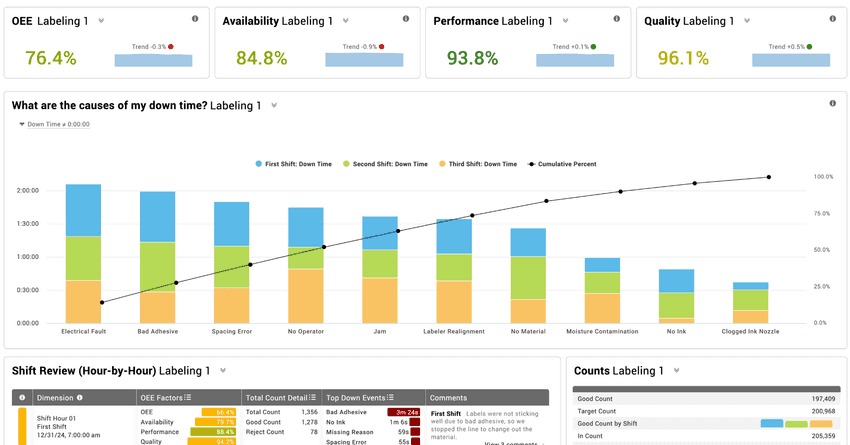

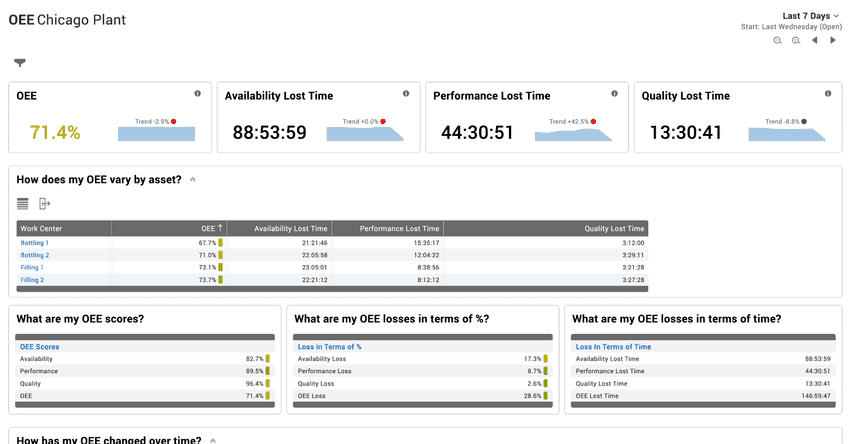

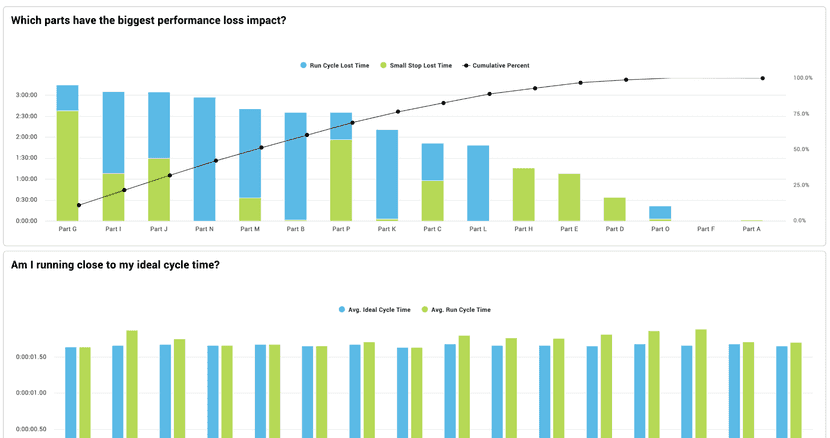

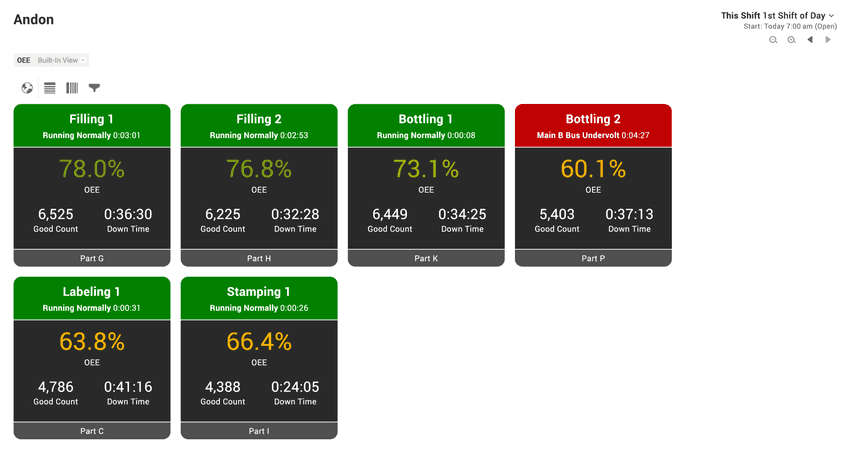

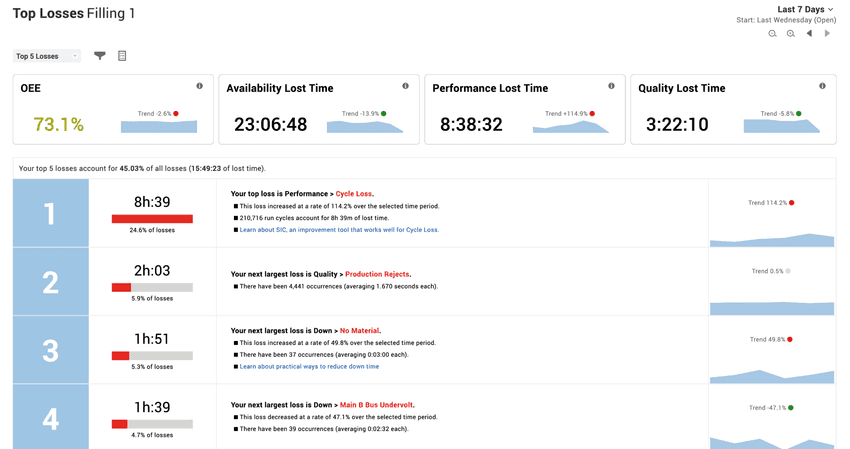

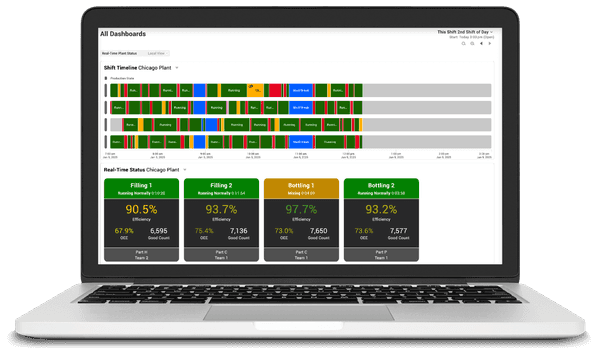

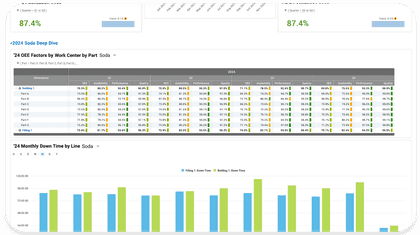

This is What Your Managers See

Actionable data, anywhere and everywhere.

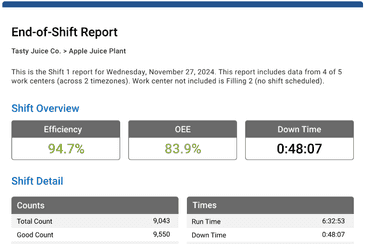

With XL, you’re equipped to make impactful, data-driven decisions. A complete, real-time and historical view of your plant floor from your office and on the shop floor. Track production. Hit your targets. Attack issues immediately.

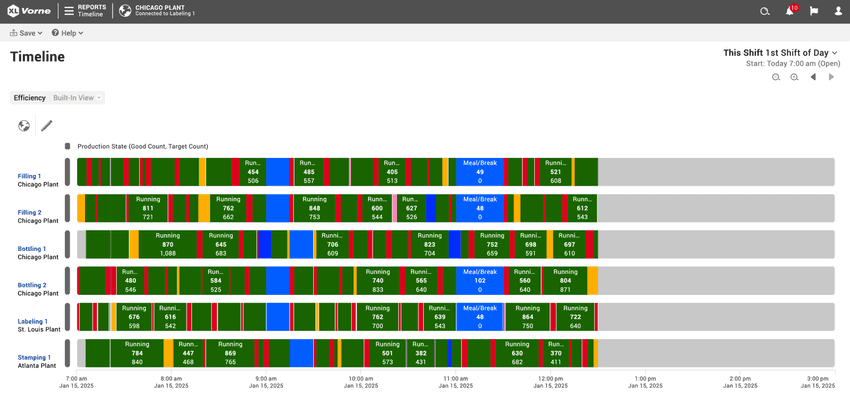

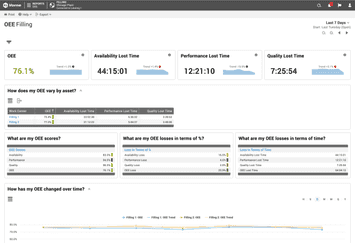

Receive automated email reports and email or text alerts. Access built-in reports or create your own custom reports and dashboards. Combine essential metrics with interactive tools for easy exploration, like:

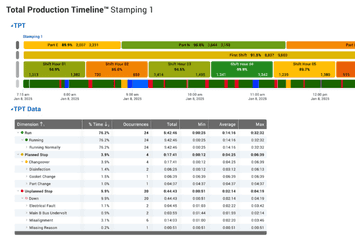

- Shift timeline by Production State events,

- Downtime Pareto by Reason,

- Andon production review, and

- OEE deep dive.

Visualize performance instantly, monitor downtime, and identify opportunities for improvement—all in one user-friendly platform.

XL’s adaptable reporting lets you see the data you need, exactly how you need it.

XL at a Glance

It’s all about the numbers.

We’ve been continually expanding and enhancing the XL platform since 2002.

XL Reports and Dashboards

Your data, your way.

XL’s vast collection of built-in reports ensures you hit the ground running as soon as you begin collecting data. As you identify your own favorite KPIs and key areas where you want to focus, explore our easy tools to create your very own custom dashboards. Visualize your data, your way.

By the Numbers

Simple to understand, infinite possibilities.

Built-In Reports

Full-featured reporting and analytics including built-in reports and instant export to Microsoft Excel.

- Changeover

- Down Time

- Hidden Factory

- Six Big Losses

- Teams and Labor

- Total Production Timeline

- Many more!

Metrics

Choose from over 140 metrics (available both in real time, as well as for historical analytics).

- OEE

- Cycle Loss

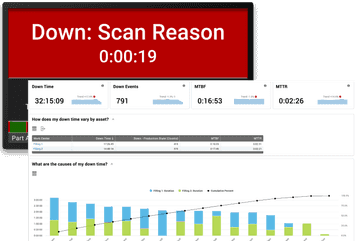

- MTBF and MTTR

- Run Time

- TEEP

- Target Count

- Many more!

Custom Reports

Create custom dashboards by combining any of our pre-built visualizations to craft your perfect production report.

- Andon

- Chart

- Chronogram

- Event List

- KPI

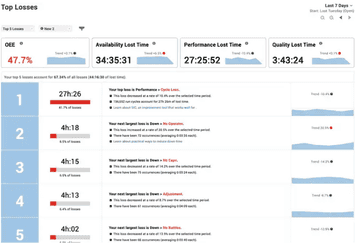

- Top Losses

- Many more!

Feature Favorites

A small snippet of the big picture.

Here are six XL features that our users love. Probably because many features are directly driven by user feedback!

Accurate Automatic Downtime Tracking

Most companies are shocked to discover their true downtime, and you’re about to see yours. Capture downtime reasons where they happen, when they happen. Every second, every detail, every time.

Data Anywhere, Data Everywhere

With the Andon report, see real-time data from every monitored line in your plant, even when you aren’t on the plant floor. Instantly know where attention is needed.

Automated Email Reports & Text Alerts

Instantly receive end-of-shift reports in your inbox and see if your team hit their targets. Receive automatic email and text alerts to see problems that need immediate attention.

Configurable Reports and Exports

Quickly create dashboards with our nine powerful built-in widgets. Report by anything you can imagine - Shift, Part, Team, Reason, and more. Your data belongs to you. Report in XL, and export to Excel.

Instant Shift Visibility

See a precise production timeline populate in real time. View when you’re Running and when you’re Down, in Changeover, or in Meal/Break, and why. Identify and break patterns.

Top Losses

Identify top losses with blinding clarity on what to fix next. Trend indicators and sparklines tell your story in a glance. It’s your built-in Continuous Improvement roadmap.

Will XL Work for Your Industry?

Yes! If you can count it, XL can measure it.

Part of the magic of XL is that it drops seamlessly into any process that provides counts or cycles. Connect to all of your equipment with one platform, and enjoy a standardized and consistent set of data and reports. Take a look at some of our customers, or view examples of industries where XL has excelled:

XL Easy

A perfect balance of simple and powerful.

Creating a user experience that is both simple and powerful is at the forefront of everything we do. We call it XL Easy. Easy to buy. Easy to install. Easy to configure. Easy to use. We also include free technical support to make your implementation even easier.

Affordable One-Time Cost

No software to install, no servers to maintain, no recurring fees, no contracts, unlimited users. You fully own and fully control your data!

In-Stock Units and Quick Setup

XL is in stock and ready to ship. It’s also incredibly easy to deploy. Two sensors, and about eight hours of your time. Done!

Intuitive Reporting Interface

XL makes it quick and easy to create custom dashboards using a combination of configurable pre-built data visualizations and live controls.

Achieve Sustained Improvement

Low cost. High impact. Even better value.

Many of our users have XL devices that have been operating in their factories for 10+ years. Our platform continually provides value to your team. Vorne XL benefits include:

- Built to last

- Free support

- Impressive ROI

- Trusted by industry leaders

The Collection

One platform. Choose your scoreboard.

The main difference between XL models is the scoreboard. All XL models enable you to access the same comprehensive set of production data and browser-based reports delivered by the XL IIoT engine. Choose the scoreboard that best matches your factory aesthetic and environment.

Easy Data Access

Your XL. Your Data.

- Everything you need instantly: All of your users can access data as soon as you connect XL to your network.

- 4GB on-board to store 3 to 5 years of data: All the historical production data you need to improve.

- No cloud requirement, no IT headaches: XL devices operate within your firewall, giving you greater IT security.

- Excel integration: Export any tabular data to Excel with just two clicks.

- SQL integration: Automatically export data into a SQL database to report in PowerBI (optional).

Why XL?

Monitor simply. Improve quickly.

Every single time we develop a feature for XL, we ask ourselves, “How can we make this as simple as possible for our users?” Our goal is for you to be able to immediately start improving your processes. Your focus should be on improving the bottom line, not struggling with overcomplicated new tools!

- Accurate, Automated Data Collection: XL captures data directly from sensors on your line for automated counts, cycles, and downtime detection, ensuring consistent and unbiased information (140+ metrics).

- Real-Time Visualization and Monitoring: XL provides plant floor visualization and live updates in the web page interface, allowing teams to monitor production and react instantly.

- Minimal Operator Reliance: XL’s automated data capture reduces dependence on and work for operators. Operators simply scan down reasons, and optionally, add comments.

- Detailed Reports and Alerts: XL offers curated data through an extensive collection of visual dashboards, as well as end of shift reports and alerts sent straight to your inbox.

- Hassle-Free with Proven Results: XL is easy to set up and use, so you’ll be able to take advantage of all of its capabilities, as opposed to a complex tool that sits and gathers dust. Don’t just take our word for it, take a look at our many testimonials direct from people who have used XL in their factories!

XL FAQs

You asked, we answered.

Get Started With XL

Try XL for yourself. Free 90-day trial with full support.

While XL can be up and running in as little as 8 hours, getting the most out of its features takes a bit more time. That’s why we offer a free 90-day trial. We want you to be able to test XL in your plant to see how it works on your line and integrates with your current systems before committing to a purchase! Our trial process is proven - 92.8% of companies that try XL, buy XL.

We are also here to help guide you through the 12 week trial process. We’ll walk you through XL in a one-on-one product tour before it arrives so you can hit the ground running, and we’ll help you configure your XL device. Plus, your dedicated Customer Success Specialist will be available to answer any questions that come up as you use XL!