Improve OEE: Resources from Vorne

We are passionate about helping companies like yours improve their manufacturing productivity. Explore these free resources (which correspond to the five wins and five sins of OEE) created by Vorne experts to learn more about the many ways you can approach an OEE improvement project. You can download the slide deck from our Improve OEE presentation here. You can also download a dozen of our favorite improvement topics here.

Dive Deep Into Each Win and Sin

Read on for an overview of each of the five sins and five wins of OEE, and click through for more content about the wins and sins that interest you most.

Five Sins

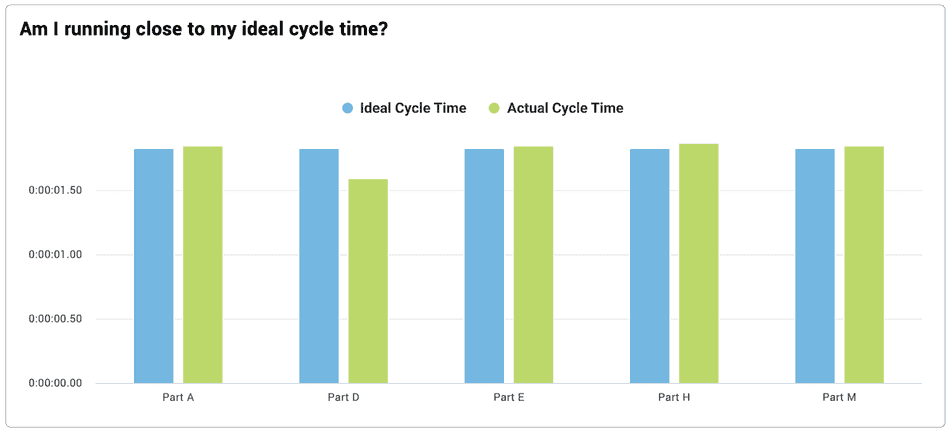

1. Un-Ideal Cycle Time

You would be astonished by how often we see ideal cycle times that are inaccurate. It is easily the most common source of bad OEE data. Why? Either because 'budget' or 'standard' times are used from an MES or ERP system (which includes allocations for losses) or ICTs are not set for different parts. Ideal Cycle Time should be the absolute fastest time per part that can be achieved by your manufacturing process on a sustained basis.

If your ICT is incorrect, you may be focusing on the wrong things. Budget or standard speeds are useful metrics for production planning, but when used to calculate OEE, they artificially inflate your OEE score, hide losses, and limit your ability to improve.

Here are some resources to help you master Ideal Cycle Time:

1

Learn how to accurately track cycle time loss.

2

Exploring, comparing, and contrasting cycle metrics makes them easier to understand.

3

Many manufacturing lines are only 60% productive, leaving many opportunities for improvement.

4

Learn about our recommended OEE calculation.

5

Don't get hung up on the technical details of OEE.

6

Here are answers to the questions we encounter most frequently when applying the concept of OEE.

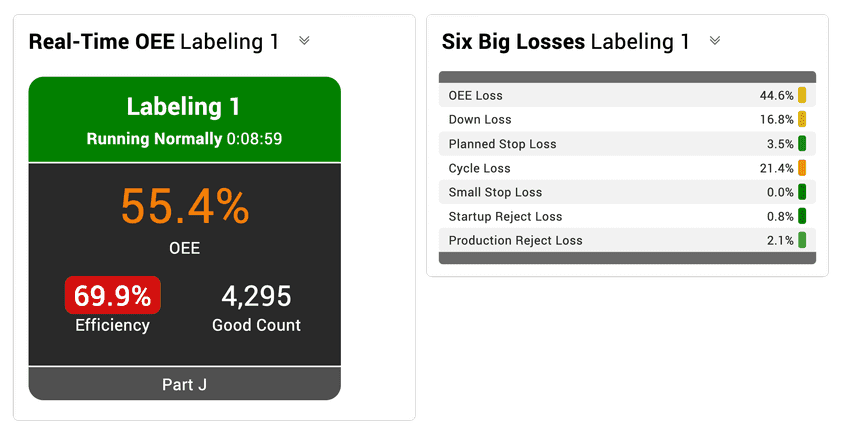

2. Hiding Losses

OEE should be a brutal measure. You should be willing to wince in pain when you see your “true” OEE score. Treat it as an opportunity. The more losses that are exposed, the more fertile ground you’ll have for improvement. If time can be used for value-added production (i.e., manufacturing to meet customer needs as opposed to manufacturing for inventory), it should be included in OEE. Changeover time - include it as a loss. Parts that require rework - include them as a loss.

No pain, no gain. An OEE score that includes all losses provides you with more opportunities for improvement. If you hide losses by excluding them from OEE, it is much harder to take steps to improve them.

Here are some resources to help you master measurement of your losses:

1

Availability, Performance, and Quality tell you where you should focus your improvement efforts.

2

The Six Big Losses categorize equipment-based losses and provide a target for action.

3

Before purchasing new equipment, ensure you are collecting accurate production data.

4

TEEP shows how much potential you have to increase throughput with equipment you already own.

5

Understanding the time concealed in your hidden factory helps unlock your full production potential.

6

Single-Minute Exchange of Die is a widely accepted best practice for reducing changeover times.

3. Info Without Insight

Many companies make decisions based on an incomplete data foundation. It is essential to build an accurate and automated information foundation to support OEE. But what does that mean? At a minimum, you should be tracking the three OEE factors (Availability, Performance, and Quality) further broken into the Six Big Losses (Unplanned Stops, Planned Stops, Slow Cycles, Small Stops, Startup Rejects, Production Rejects), with reason codes for down events and rejects.

Insufficient, inaccurate, or incomplete data limits your ability to make informed decisions. Build a data foundation that enables you to pursue perfect production (manufacturing only good parts, as fast as possible, with no downtime).

Here are some resources to help you master data accuracy:

1

Implement real-time data collection to drive improvement at every level.

2

Transform data into actionable information to facilitate decision-making and actions.

3

Downtime reporting is more consistent and more useful with a manageable list of down reasons.

4

As a first step, establish consistent measurement standards and ensure downtime is captured at the constraint.

5

Optimize run time, predict behavior, test what-if scenarios, and much more with a Digital Twin.

4. Idolizing OEE

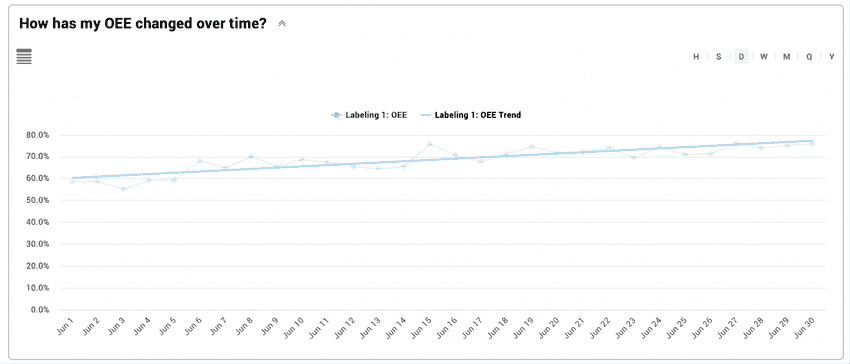

You don’t make OEE. You make products. Many companies fixate on their OEE score when their focus should be on the underlying losses and trajectory. A good OEE score is one that is improving. A great OEE score is one that adds profit to your bottom line. Set OEE targets that drive solid, incremental improvement. It’s about percentage improved - NOT percentage achieved.

The real power and value of OEE comes from understanding and acting on the underlying losses (Availability Loss, Performance Loss, and Quality Loss). Take effective action to reduce these losses and your OEE score will naturally improve.

Here are some resources to help you focus on trajectory and trends:

1

OEE measures how close you are to manufacturing only good parts, as fast as possible, with no down time.

2

Don't get hung up on the technical details of OEE.

3

There is no one ideal OEE score or OEE industry standard to use as a benchmark for every company.

4

Explore a variety of OEE topics ranging from OEE basics all the way to deep dives.

5

Learn how to reduce downtime, the largest source of lost production time for most manufacturers.

5. OEE Paralysis

Companies often maintain excellent momentum when building their information foundation, but lose that momentum when it's time to transform information into results. It's a waste to spend time and money collecting good data if you don't use it!

We recommend using IDA (Information, Decision, Action) as a framework to transform information into action, and ultimately, into results. Rather than focusing on the outcome you would like to achieve, use IDA to address top losses and results will take care of themselves.

Here are some resources to help you master transforming your data into results:

1

If you focus on information, decisions, and actions, results will follow.

2

Align people, information, decisions, and actions to the same objective for superior results.

3

IDA provides a simple and straighforward framework to improve OEE.

4

Capture detailed loss information to inform actions and improve manufacturing productivity.

5

The Six Big Losses provide an equipment-based perspective on lost production time.

6

Carefully curated KPIs support and facilitate achieving your most important goals.

Five Wins

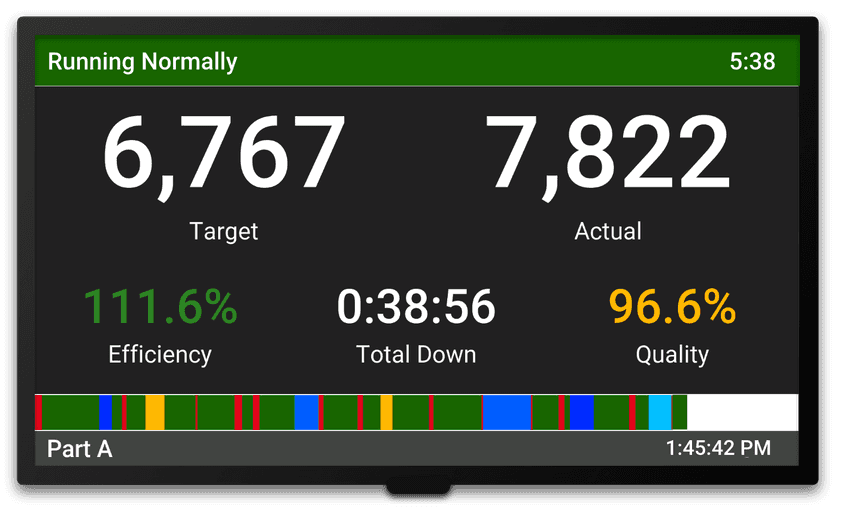

1. Win the Shift

Everyone loves to win. Information drives results. Do your operators know what success looks like? Do you provide them a very specific target during the shift? Here is what you do. Provide your operators with a real-time scoreboard that shows them an incrementing takt-based target while running and additional contextual information when the process is not running. Arm them with the motivation and information they need to win the shift.

Truth is – we don’t recommend OEE for the plant floor. OEE is abstract, making it difficult to drive improvement on the plant floor. Use Efficiency (Actual vs Target) to enable operators to win the shift, and OEE will take care of itself.

Here are some resources to help your operators win their shift:

1

Provide an opportunity for your plant floor team to win the shift by displaying real-time shift data on the plant floor.

2

Creating a visual factory enables operators to take in information as efficiently as possible.

3

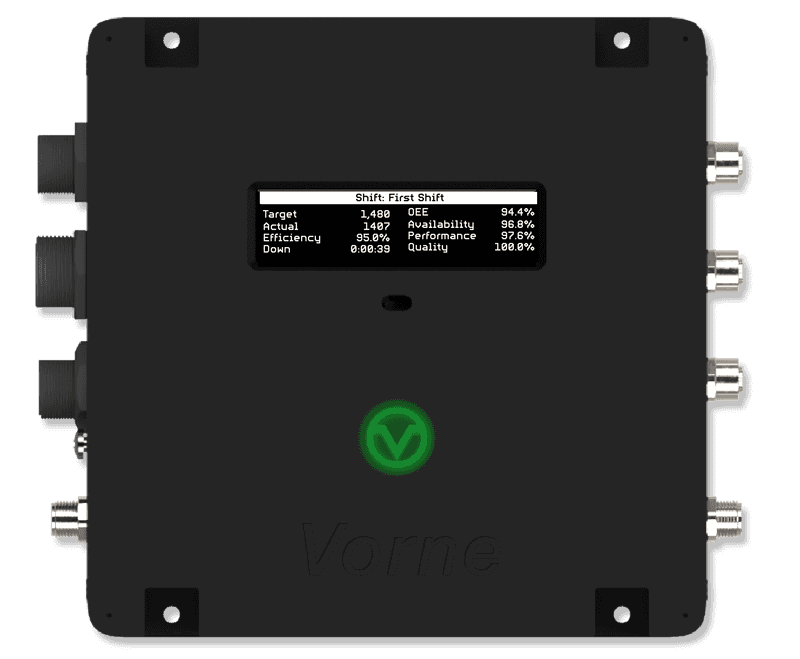

Digital OEE displays gather accurate, actionable production data and make it available to operators in real time.

4

Split the shift into short intervals, within which employees identify and implement improvement actions.

5

XL HD is a compact IIoT device with integrated hardware and software for monitoring and improving production.

2. Focus on the Constraint

Every manufacturing process has a constraint (bottleneck). Ignore everything else. It doesn’t matter. The constraint is your output - it is the point of leverage for the entire process. Focusing improvement efforts on the constraint ensures optimal use of resources and is the fastest route to improved productivity and profitability. It also tells you where to measure and improve OEE - the constraint.

Where should you focus resources? Should all equipment be improved? Should you focus on breakdowns? Changeovers? Small stops? The answers is simple. Spend time where it will meaningfully impact OEE. The constraint.

Here are some resources to help you improve your production constraint:

1

Each manufacturing process has a constraint that offers the fastest path to improved productivity.

2

The Theory of Constraints is a methodology for identifying and improving the bottleneck in a process.

3

Increase production capacity with existing equipment, not capital expenditures or outsourcing, by eliminating waste.

4

The best way to reduce costs is to eliminate waste (spend less) while increasing throughput (make more).

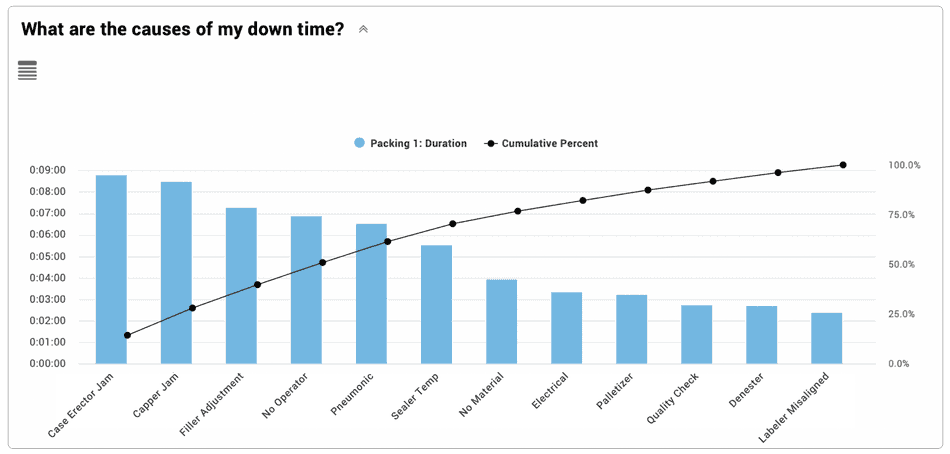

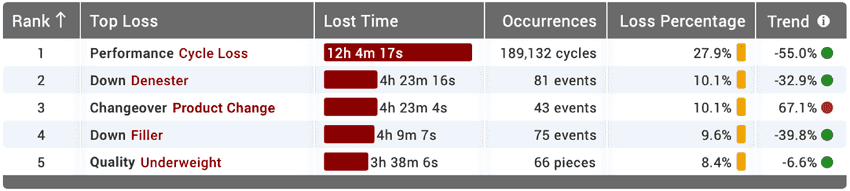

3. Rank Your Losses

Stop working on the wrong things. Fix what really impacts production. First, rank your losses by lost production time. We call it a Top Losses Report. Next, select any of the top 10 losses where your team has ideas on actions that they can take, minimal external resources are required, and actions can be taken right away. Track (capture accurate Top Loss information). Pick (select actions based on the Top Losses). Fix (implement improvement actions). Repeat.

Consistently engaging in improvement actions for your top losses is a sure-fire way to improve OEE. It ensures you are spending your time where it will have the most impact. It uses lost time as a single metric to rank all losses.

Here are some resources to help you rank your losses:

1

Improve quickly by focusing on minimizing production losses, beginning with your largest sources of loss.

2

The three OEE factors map to the Six Big Losses, a concrete framework within which to categorize your losses.

3

The true value and power of the Six Big Losses is in the path they provide to improving OEE.

4

There are many strategies to improve productivity, each with their own advantages and learning curves.

4. Democratize Data

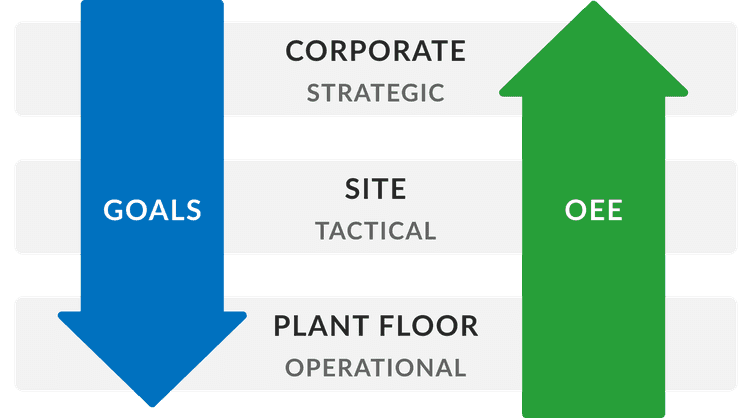

Share data with the entire team to ensure everyone is making decisions based on the same information. Deliver the right information, to the right people, at the right time. Use TAED (Target, Actual, Efficiency, Down Time) to help operators to win their shift (operational). Use Six Big Losses to understand your losses (tactical). Use OEE to track improvement over time (strategic).

By sharing data, the same accurate data foundation drives action across all levels (operational, tactical, and strategic), so everyone is, and stays, aligned.

Here are some resources to help you create a data democracy:

1

OEE software provides context through insights into your OEE factors and underlying losses.

2

Downtime tracking is only helpful if you go beyond collecting metrics to presenting, analyzing, and improving.

3

Vorne XL provides one, consistent set of data presented in a variety of reports for every level of your team.

4

Traditionally, production counting systems monitor the number of items produced, but they can do much more.

5. Escalate Exceptions

Exceptions are where losses lurk and grow. Prevent small issues from becoming big problems by creating alerts that automatically escalate issues to key team members. Use Andon alerts for operators, email alerts for supervisors, and high-threshold escalation alerts for top-level managers. React and mobilize resources as a team across all levels and departments. Speed up response time for operators, supervisors, and managers.

Improves OEE in the short term through immediate recognition of emerging issues so those issues can be addressed faster. Improves OEE in the long term through building a culture of teamwork, communication, and accountability.

Here are some resources to help you escalate exceptions:

1

Scoreboards display key information in real time so your team knows how they're doing and when to take action.

2

An Andon is a mechanism for ensuring that issues during production are immediately recognized and resolved.

3

Andons in manufacturing originated at Toyota, where operators pulled a cord when they saw a problem on the line.

4

Modern Andon Systems still work through the same three core elements: signal, alert, and resolve.